Why Error Code 498 Matters

If you’ve ever been knee-deep in troubleshooting a PLC Error Code 498 at 2 AM, you know how it can bring your entire production line to a halt. PLC error codes are the lifelines for diagnosing system health, and ignoring them is like driving a car with the check engine light on. Trust me, it won’t end well.

Specifically, PLC Error Code 498 can cripple operations. It’s notorious for causing unexpected downtimes and production losses. Imagine your production line stops in the middle of a high-volume run. You’re losing thousands of dollars every minute. That’s the kind of mess Error Code 498 can cause if not addressed promptly.

I’ll be honest, I’ve been there. I once had the pleasure of dealing with this error during the commissioning phase of a new line. We had Siemens S7-1500 PLCs, and Error Code 498 popped up just as we were about to hand over the project. It wasn’t just frustrating; it was downright chaotic. Clients waited, production schedules got delayed, and the clock ticked on our reputation. A nightmare, truly.

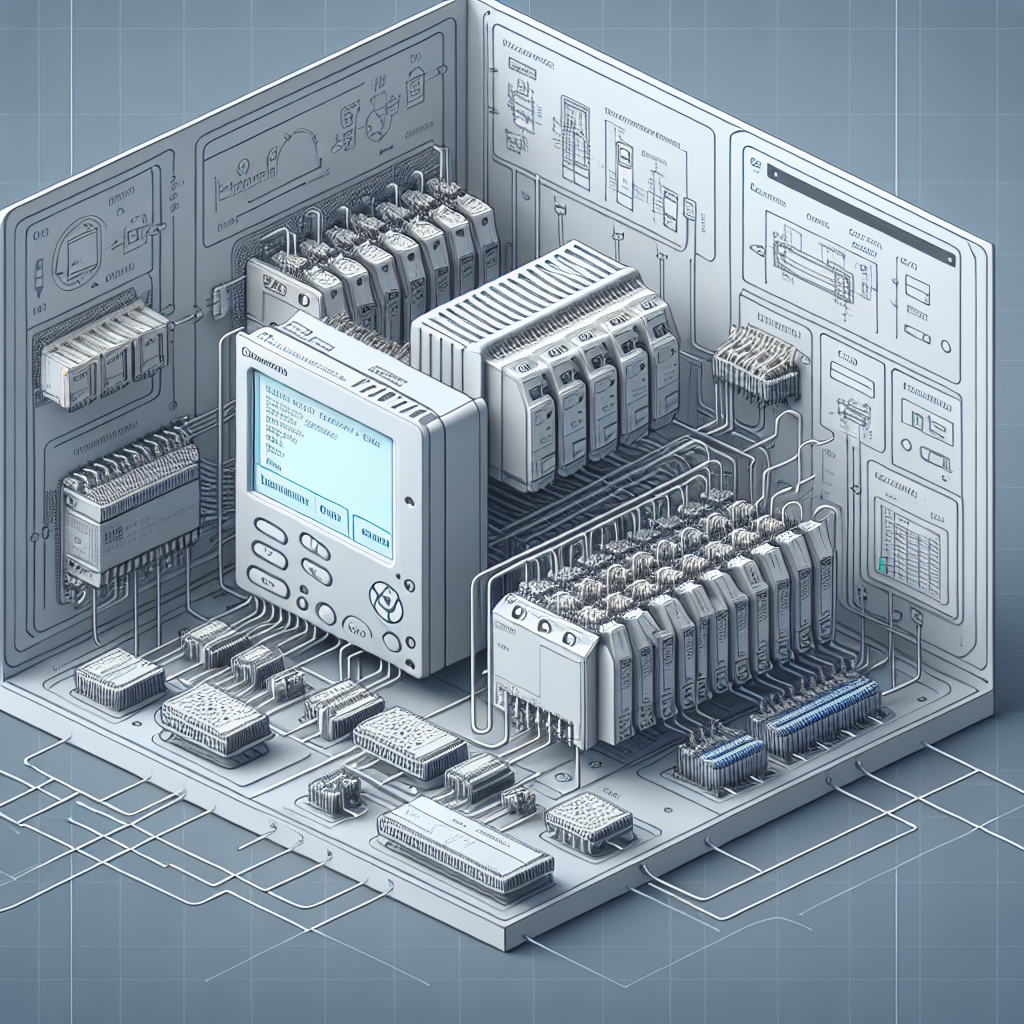

Understanding PLC Error Code 498

Common Causes

Now, let’s talk about what actually causes PLC Error Code 498. Typically, you’ll find it’s a hardware or firmware issue. Connection glitches, outdated firmware, or even a bad configuration file can trigger this headache-inducing number.

Hardware failures like faulty I/O modules or damaged communication cables often make their way to the top of the list. Moreover, firmware compatibility issues, especially during updates, commonly rear their ugly heads.

Potential Impact on Systems

So, how does this pesky error affect your operations? In my experience, it can bring a system to a grinding halt. Equipment goes offline, data collection stops, and worse, the entire automation process gets stuck in a loop of errors. You’re left staring at a screen full of red alarms, wondering where to even begin.

Here’s the thing: Error Code 498 doesn’t just affect the component where it originated. I’ve seen it cascade across systems, affecting everything from data logging to real-time monitoring. If you’re using a network of Siemens PLCs, this error might even throw your Profinet communications off balance.

Pro Tip: “Always keep your firmware updated and perform routine checks on hardware components. This significantly reduces the likelihood of encountering Error Code 498.”

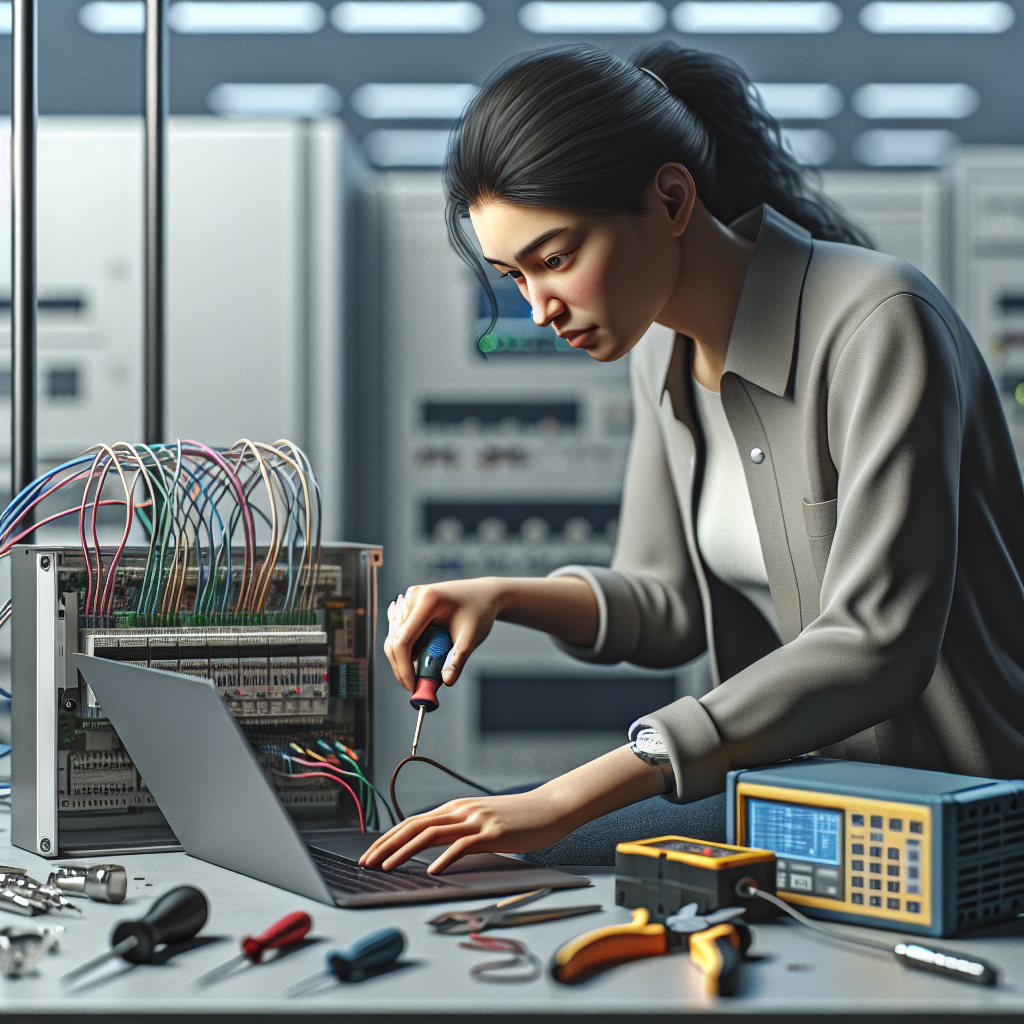

Step-by-Step Diagnosis

Initial Checks

First things first, confirm the existence of the error. Head over to your HMI or SCADA and pull up the error logs. You want to ensure that PLC Error Code 498 is indeed the culprit. Trust me, there’s nothing worse than barking up the wrong tree.

Once you’ve identified the error, check the obvious: power supply, connections, and visible hardware damage. If your system uses Siemens TIA Portal, fire it up. The diagnostics feature is your best friend here. It provides a detailed error history and status of hardware components.

Advanced Diagnostic Techniques

Okay, so you’ve confirmed the error. Now, let’s get into the nitty-gritty. Use Siemens TIA Portal’s online diagnostic tools to dive deeper. Navigate to the “Online & Diagnostics” section for a real-time status of your PLCs. It’ll help you identify which exact component is causing the issue.

Furthermore, look for patterns in system behavior. Do you notice a surge in errors during specific operations? Could it be that the error coincides with a certain production stage? This info will guide your diagnosis.

As a next step, examine the error logs carefully. Often, accompanying error codes provide a breadcrumb trail. These codes give insights into what might be linked to Error Code 498, like a peripheral device failure or network instability.

The real trick is to cross-reference these logs with your system’s operation timeline. For instance, if the error pops up during a firmware update, you might have a compatibility issue. This detective work helps you narrow down potential causes effectively.

For those using older PLC models or legacy systems, don’t worry. A USB-to-RS232 converter can help you pull logs and run diagnostics even on dinosaurs like the S7-200 series.

From my experience: “Never underestimate the power of a well-maintained error log. They’re not just records; they’re your roadmap to resolution.”

In addition, if your system involves Modbus communication, make sure your parameters are correct. A misconfigured Master-Slave setup can often lead to recurring issues, including our friend, Error Code 498.

Meanwhile, if you’ve tried everything and the error persists, it might be time to get a second pair of eyes. Sometimes, an experienced colleague will notice something you’ve overlooked. We’ve all been there, and it’s nothing to be embarrassed about.

Finally, it might be wise to consult external documentation for your specific PLC model. Siemens and other manufacturers provide extensive resources online. You can find detailed troubleshooting guides directly from Siemens Support or other official channels.

All these steps should help you get a handle on PLC Error Code 498. However, the real challenge is fixing it, and that’s where our next discussion will lead.

Practical Solutions and Fixes

Hardware-Related Fixes

So you’ve diagnosed PLC Error Code 498 and narrowed it down to hardware. Now what? First, check for any loose wiring or connections. I’ve seen countless errors traced back to a simple loose terminal. Make sure your connections are snug, whether they’re RJ45 connectors or DB9s. Next, inspect any component that might be showing signs of wear and tear. An aging power supply can wreak havoc on your system, for instance.

Replacing faulty components like I/O modules or even the CPU itself might be necessary. If you’re working with Allen Bradley or Siemens, getting a replacement part is straightforward. Keep spares on hand if your budget allows. Trust me, it saves you from those overnight shipping fees.

Software and Configuration Adjustments

Firmware updates are another common fix for PLC Error Code 498. Manufacturers like Siemens and Rockwell frequently release updates to patch known issues. Download the latest firmware from your PLC’s manufacturer’s website and follow their update process. Don’t skip the backup step! I once lost valuable configuration data because I rushed through an update.

After updating, reset your configurations. Sometimes, an issue as simple as a misconfigured parameter can trigger error codes. Ensure that everything aligns with the latest operating parameters from your vendor. For instance, Siemens’ TIA Portal makes it relatively easy to configure settings once your firmware is up-to-date.

As a real-world example, I recently updated firmware on a Mitsubishi Q-series PLC. Prior to the update, Error Code 498 was a recurring headache. Post-update, the error vanished, and we haven’t seen it since. It’s proof that sometimes, a software update is all you need to get things smooth again.

Preventing Future Occurrences

Regular Maintenance

Let’s talk about how to keep PLC Error Code 498 at bay. Regular maintenance is your first line of defense. Schedule these checks like you’d schedule an oil change for your car. Inspect wiring, check power supplies, and clean air filters. Dust and debris can accumulate, causing overheating and other issues.

Monitoring and Alerts

Set up alerts and monitoring systems to catch errors early. SCADA systems can be configured to send alerts directly to your phone or email. In my experience, catching an error before it snowballs into a major problem saves you time and money. Additionally, invest in tools that provide real-time data on your PLC’s performance. This way, you’re not just reacting to issues; you’re anticipating them.

Here’s a tip: log your system’s performance metrics. It’ll help you spot trends and prevent small issues from becoming big headaches.

Common Mistakes to Avoid

When dealing with PLC Error Code 498, there are a few common mistakes you’ll want to steer clear of. Trust me, I’ve seen these trip up even the most experienced engineers.

- Ignoring Firmware Updates: Skipping firmware updates can lead to compatibility issues and known bugs that manufacturers have already patched. Keep your systems up-to-date to avoid unnecessary headaches.

- Overlooking Loose Connections: It’s easy to assume complex errors require complex solutions, but sometimes it’s just a loose wire causing the chaos. Always check your connections first.

- Skipping Configuration Checks: Misconfigured settings can be a silent killer. After any update or hardware change, double-check your configurations to ensure they’re correct.

- Neglecting Regular Maintenance: Regularly scheduled maintenance might seem like a chore, but it can catch small issues before they grow. Don’t let minor problems snowball into major ones.

- Not Using Diagnostic Tools: Failing to utilize available diagnostic tools can leave you in the dark. Tools like Siemens TIA Portal are invaluable for pinpointing the exact cause of errors.

Key Takeaways and Quick Reference

Here’s a quick summary of how to tackle PLC Error Code 498. First, diagnose the issue—check both hardware and software. Replace faulty components and update firmware as needed. Regular maintenance and monitoring will help prevent future occurrences.

- Always check for loose connections first.

- Keep firmware updated; it solves more problems than you’d think.

- Maintain a robust monitoring system for early detection.

Honestly, maintaining a smooth-running PLC system isn’t rocket science, but it does require diligence. Follow these steps, and you’ll be well on your way to minimizing unexpected downtime.

Frequently Asked Questions

What is the primary cause of PLC Error Code 498?

In my experience, PLC Error Code 498 often arises from outdated firmware or configuration settings. However, hardware issues, like failing I/O modules or loose connections, can also trigger this error. It’s essential to pinpoint the root cause through a thorough diagnosis.

How long does it typically take to fix Error Code 498?

The time it takes to fix PLC Error Code 498 depends on its complexity. You might resolve a loose connection in minutes, but firmware updates or replacing hardware can take several hours. Plan accordingly, especially if production is at stake.

Can Error Code 498 lead to system downtime?

Yes, if left unchecked, PLC Error Code 498 can lead to system downtime. That’s why early detection through monitoring systems is crucial. Address the issue promptly to minimize impact on production schedules.

Is it possible to prevent Error Code 498 entirely?

While you can’t prevent all occurrences of PLC Error Code 498, regular maintenance and firmware updates significantly reduce the risk. Implementing monitoring systems also plays a vital role in early detection and prevention.

What tools are best for diagnosing PLC errors?

Diagnostic software like Siemens’ TIA Portal and Rockwell’s Studio 5000 are essential for troubleshooting PLC errors. Multimeters and network analyzers also help identify hardware issues and network problems. Having these tools in your arsenal is invaluable.

Real-World Anecdotes

I remember one site where we faced Error Code 498 every week. It turned out a rat had chewed through the cabling. We only figured it out after placing cameras around the panels and catching the culprit in the act! Another time, I spent two days troubleshooting what seemed like a firmware issue but actually came down to a single misconfigured network switch causing Profinet communication failures.

And then there was the time I was called in because the error only appeared during night shifts. Turns out, the night crew used an old laptop for logging data, and its outdated software triggered the error. Funny enough, replacing that laptop with a newer model resolved everything overnight—literally!

I’ve been down this road many times, and hopefully, my experience can save you some headaches. Keep your systems updated, stay vigilant with maintenance, and you’ll find that PLC Error Code 498 becomes a rare nuisance rather than a frequent visitor. Feel free to share your own tips or questions in the comments on industrialgyan.com. Let’s learn from each other.

I am an electrical & automation engineer with extensive experience in Design, PLC programming, SCADA development, and IoT integration. I have a strong background in the industry, focusing on the Design & Development of Hardware, Software &Industry 4.0 technologies, and the integration of intelligent manufacturing systems.

I have a deep understanding of electrical principles and am proficient in various programming languages, including Ladder Logic, Structured Text, and Python. In addition, I have experience with various PLC, SCADA & IoT technologies and a track record of successful integration projects for various clients.