Convert electrical power into mechanical power using a motor. Induction motors have slip-ring type induction motors. It has many advantages over other motors like AC motors, and DC motors.

What is Slip Ring Induction Motor?

Mostly use Slip ring Induction motors for high starting torque, low initial current, and high power factor value, also known as Wound-type induction motors.. It operates in 3 phase power supply and produces a rotational magnetic field (RMF) in the stator winding. The Cylindrical type rotor experiences a force by producing RMF in the stationary winding. It is a type of asynchronous motor because of stator value and rotor value do not exactly match.

These types of motors used in various applications:-

- Elevator

- Cranes

- High starting torque Applications

Slip Ring Induction motors (Stator)

Construction:-

So here we start the discussion of the construction of the three-phase slip ring induction motors. So basically motors are divided into two parts as given below:-

- Stator

- Rotor

Stator:-

The stator is a stationary part of the Motor and 3 Phase AC delta-connected winding produces a Rotational Magnetic field. It is known as the stator.

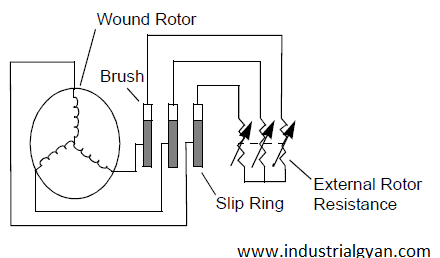

Rotor:-

The rotor is a rotatory part of the motor and cylindrical laminated core-type steel. the winding is placed at 120 degrees. the rotator experiences the force developed by the rotating magnetic field (RMF) in the stator.

Working of the Slip ring induction motors:-

The Slip ring induction motors are based on the principle of the Faraday law of Electromagnetic Induction. Stator windings connected through the 3 Phase AC supply according to the faraday law of electromagnetic induction generate a rotating magnetic field that induces flux in the rotor so experiencing the torque enables the rotation.

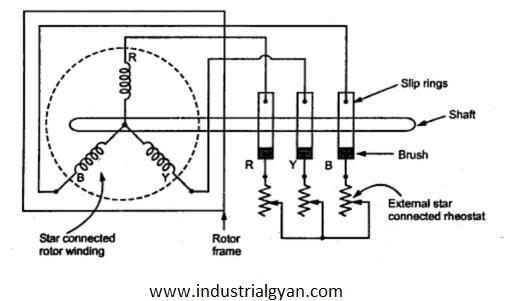

Connection diagram of Slip ring induction motor

Speed control of slip ring induction motor:-

Control the speed of slip ring induction motors according to application requirements using the two types provided below.:-

- Rheostat control method.

- Cascade control method.

Rheostat speed control method:-

In this method, we use the external resistance (Rheostat) in the connection of the motor the control the power supply of the motor. By controlling the incoming power supply of the motor we can easily control the speed of the motor. Using the Rheostat that is increasing the cost of the operation.

Torque T = S/R

Cascade speed control method:-

In this method, we use two motors for the operation of both motors connected to the same shaft. So one motor is connected to the 3-phase AC power supply and another one is connected through the induced emf from the slip rings of the first motor. Both motors rotate at the same speed.

Characteristics of the slip ring induction motor:-

The slip-ring induction motor has high starting torque and low starting current because of the external resistance. The speed is maximum at no load and reduces according to the increases in the load. Control the speed by 5% by using the external resistance in the motor.

Application:-

- A high starting torque application like lift, cranes.

- Multiple times of torque produces.

- To know more information please visit http://167.71.225.150/

Disadvantages:-

- The high initial cost is more expensive than the squirrel case induction motor.

- Efficiency is Low.

- High Copper Loss.

Top motor manufacturers:-

I am a highly motivated and skilled individual with a passion for Electrical engineering. I have 1 year of experience in Robotics and Electrical engineering, which has allowed me to develop a strong set of skills in PLC, Painting Robots, SCADA. I am a quick learner and am always looking for new challenges and opportunities to expand my knowledge and skills. I am a team player and enjoy working with others to achieve a common goal. Successfully completed many projects for a various clients in the automobile sector.

Thank You