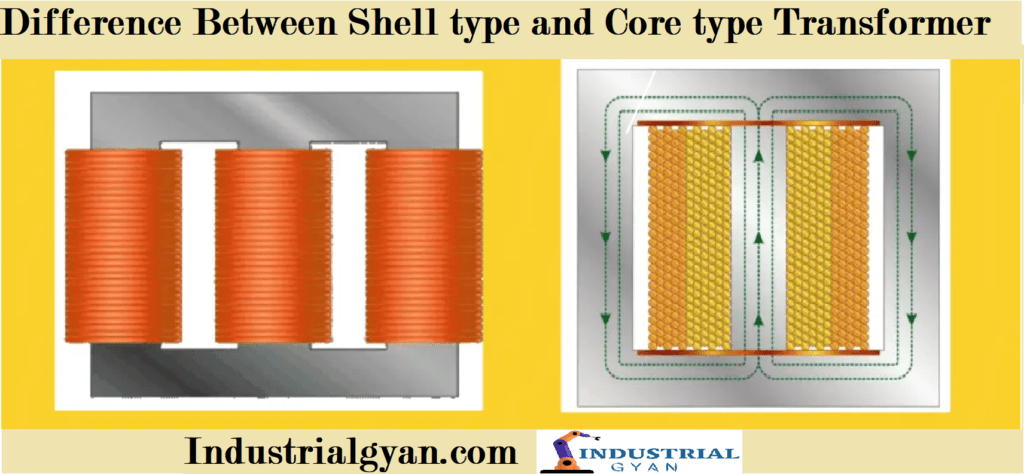

Difference Between Shell Type and Core Type Transformer

Today we will discuss the Difference between shell type and core type transformer, Transformers play a crucial role in electrical power systems, transferring energy between circuits. Two common types of transformers are shell type and core type. In this article, we’ll explore the distinctions between these two types and understand their unique characteristics.

Introduction

Transformers are vital in power transmission and distribution systems. They step up or step down voltage levels as required by different electrical circuits. Shell-type and core-type transformers are prevalent designs, each with its own advantages and disadvantages.

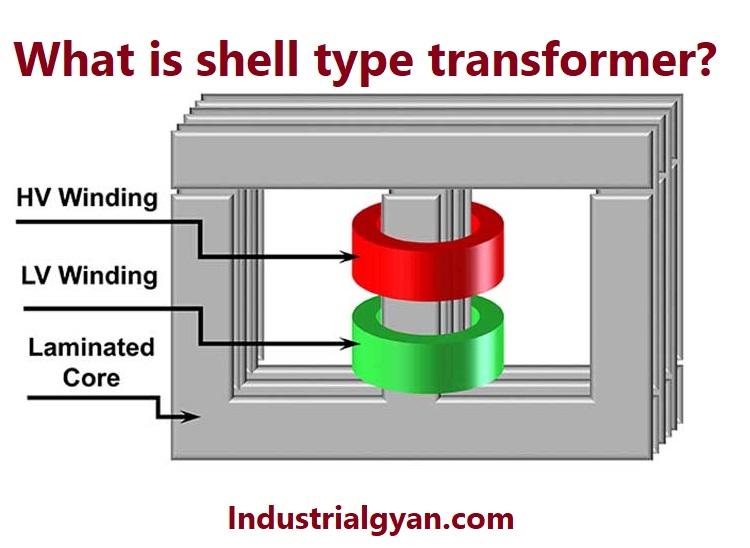

Definition of Shell Type Transformer

A shell-type transformer, also known as a core-form transformer, features a core that surrounds the windings. The windings are usually divided into multiple coils concentrically placed around the core. Shell-type transformers are commonly used for low and medium-voltage applications.

Definition of Core Type Transformer

A core-type transformer, also referred to as a shell-form transformer, has a core divided into two halves, with the windings placed in between. The windings are typically cylindrical and surround the core. Core-type transformers are widely used for high-voltage applications.

Construction of Shell Type Transformer

In shell type transformers, the windings are placed on the outside of the core. The core is made of laminated sheets or stacked iron cores to minimize eddy current losses. The windings consist of copper or aluminum conductors and are placed around the core concentrically. This design allows for better heat dissipation and easy cooling.

Construction of Core Type Transformer

In core type transformers, the windings are placed between the two halves of the core. The core consists of laminated iron sheets, insulated to minimize losses. The windings are cylindrical and surround the core, resulting in a more compact design compared to shell-type transformers. The core-type design offers better mechanical stability and lower leakage flux.

Design Considerations

When designing transformers, voltage rating, power rating, cooling system, and efficiency requirements must be considered. Shell-type and core-type transformers share common considerations, but they have specific design considerations as well.

Voltage Rating

Shell-type transformers are suitable for low and medium-voltage applications, typically ranging from a few hundred volts to several thousand volts. Core-type transformers, on the other hand, are commonly used for high-voltage applications, typically above several thousand volts.

Power Rating

Both shell-type and core-type transformers can handle a wide range of power ratings. The power rating depends on factors such as core size, number of windings, and conductor material used. Both types can be designed to handle small to large power capacities.

Cooling System

Cooling is crucial to prevent overheating in transformers. Shell-type transformers often use natural air circulation for cooling as the windings are exposed. Core-type transformers usually employ oil or forced air cooling systems to maintain optimal operating temperatures.

Advantages of Shell Type Transformer

- Better cooling efficiency due to exposed windings.

- Easier manufacturing and assembly.

- Lower losses and higher efficiency.

- Improved mechanical strength and stability.

- Lower risk of leakage flux.

Advantages of Core Type Transformer

- Compact design, saving installation space.

- Better resistance to short circuits due to winding location.

- Lower manufacturing costs for high voltage applications.

- Better voltage regulation and lower leakage inductance.

- Suitable for high-power applications.

Disadvantages of Shell Type Transformer

- Increased risk of insulation failure due to exposed windings.

- Higher losses in the windings due to greater exposure to external factors.

- Limited applications in high voltage systems.

- Higher cost for larger power ratings.

- Reduced voltage regulation capabilities.

Disadvantages of Core Type Transformer

- Limited cooling options due to compact design.

- More complex manufacturing process.

- Reduced mechanical stability.

- Higher risk of leakage flux.

- Higher losses compared to shell-type transformers.

Applications of Shell Type Transformer

Shell-type transformers are commonly used in various applications, including:

- Power distribution networks.

- Industrial applications for voltage transformation and power supply.

- Low voltage applications in buildings and residential complexes.

- Renewable energy systems, such as solar and wind power installations.

- Railways and transportation systems.

Applications of Core Type Transformer

Core-type transformers find applications in:

- High voltage transmission systems.

- Power generation plants, including thermal, hydro, and nuclear power plants.

- Large-scale industrial installations with high power requirements.

- Grid substations and interconnection points.

- Heavy machinery and equipment require a high power supply.

Cost Comparison

Shell type transformers are generally more expensive than core-type transformers, especially for higher power ratings. Shell-type transformers require additional materials and labor during construction, resulting in increased costs. However, specific requirements and applications should be considered when comparing costs.

Efficiency Comparison

Both shell-type and core-type transformers can achieve high levels of efficiency when designed and operated optimally. Shell-type transformers offer better cooling capabilities, resulting in lower losses and higher efficiency. Core-type transformers, with their compact design, exhibit lower losses due to reduced winding exposure.

Conclusion

In conclusion, the choice between shell-type and core-type transformers depends on various factors, including voltage requirements, power rating, cooling system, and cost considerations. Shell-type transformers provide better cooling and mechanical stability, making them suitable for low and medium-voltage applications. Core-type transformers are compact, cost-effective, and preferred for high voltage and high power applications. Understanding the differences between these transformer types enables engineers and designers to make informed decisions based on the specific needs of their electrical systems.

FAQs

1. Which type of transformer is more suitable for low-voltage applications?

Shell-type transformers are more suitable for low-voltage applications due to their better cooling efficiency and mechanical strength.

2. What are the advantages of core-type transformers?

Core-type transformers offer a compact design, better resistance to short circuits, lower manufacturing costs for high-voltage applications, improved voltage regulation, and suitability for high power applications.

3. Are shell-type transformers more expensive than core-type transformers?

Yes, shell-type transformers are generally more expensive, especially for higher power ratings, due to their construction and additional materials.

4. In which applications are shell-type transformers commonly used?

Shell-type transformers are commonly used in power distribution networks, industrial applications, low-voltage systems, renewable energy systems, and railways.

5. What factors should be considered when choosing between shell type and core type transformers?

Factors to consider include voltage rating, power rating, cooling system requirements, efficiency, and specific application needs.

You can follow us on LinkedIn

I am an electrical & automation engineer with extensive experience in Design, PLC programming, SCADA development, and IoT integration. I have a strong background in the industry, focusing on the Design & Development of Hardware, Software &Industry 4.0 technologies, and the integration of intelligent manufacturing systems.

I have a deep understanding of electrical principles and am proficient in various programming languages, including Ladder Logic, Structured Text, and Python. In addition, I have experience with various PLC, SCADA & IoT technologies and a track record of successful integration projects for various clients.