Are you curious about the process of electron beam machining (EBM)? In this article, we will explore the diagram and technical aspects of EBM, its advantages, and its various applications in different industries. With discussed the electron beam machining diagram.

Introduction

- Definition of EBM

- A brief history of EBM

- Significance of EBM in modern industries

EBM Process Diagram

- Components of the EBM system

- Working principle of EBM

- Types of EBM processes

- Comparison with other machining techniques

Electron beam machining diagram

Advantages of EBM

- High precision and accuracy

- Low heat affected zone (HAZ)

- Suitable for different materials

- Cost-effective and efficient

- Environmentally friendly

Applications of EBM

- Aerospace industry

- Medical industry

- Automotive industry

- Electronics industry

- Tool and die making

- Research and development

EBM System Design and Optimization

- Electron gun design and optimization

- Beam focusing system

- Vacuum system

- Power supply and control system

Challenges and Limitations of EBM

- Safety concerns

- Surface roughness and quality

- Size limitations

- High equipment and maintenance costs

- Limited availability of skilled technicians

Future of EBM

- Advancements in technology

- Potential applications in new fields

- Integration with other technologies

Conclusion

In conclusion, electron beam machining is a highly precise and efficient process that has various advantages and applications in different industries. While there are some limitations and challenges, the future of EBM looks promising with continued advancements in technology and integration with other technologies.

FAQs

- How does EBM compare with other machining techniques?

- What materials can be machined with EBM?

- Is EBM a safe process?

- How can EBM be optimized for different applications?

- What are the potential future applications of EBM?

Certainly, here is the rest of the article:

EBM Process Diagram

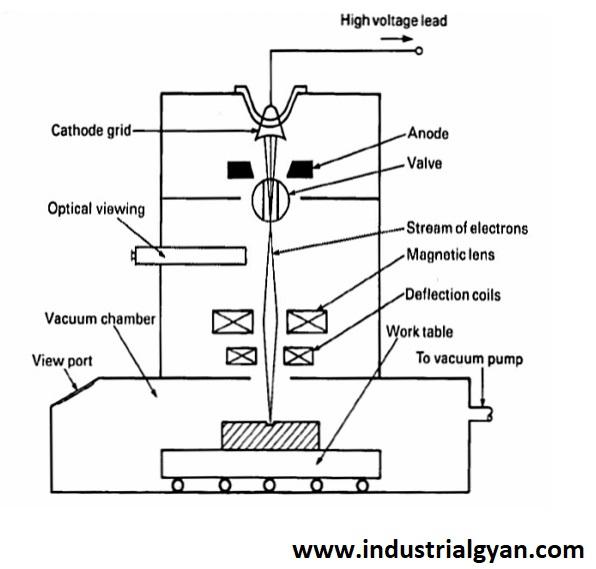

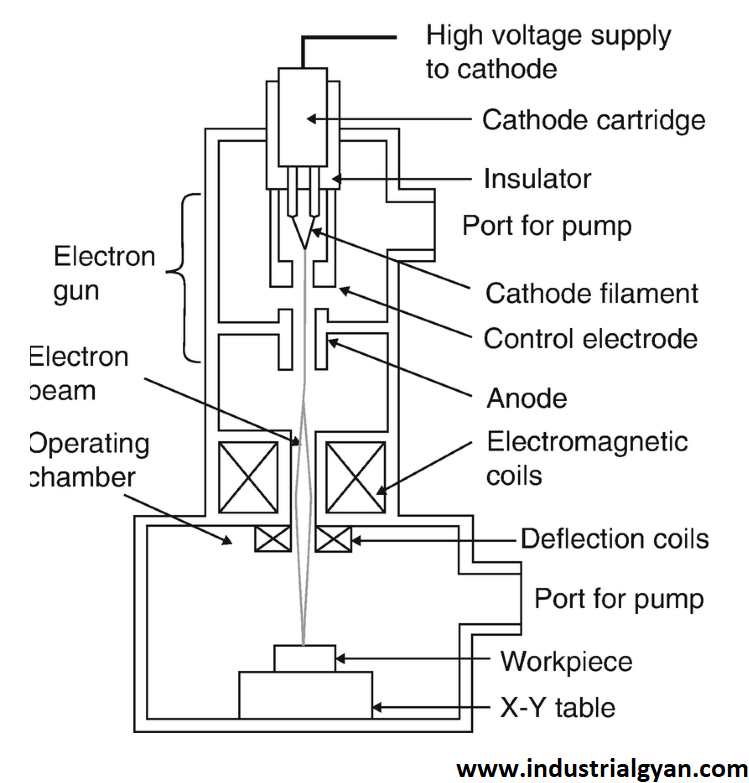

The electron beam machining process involves a high-energy beam of electrons that is directed at the workpiece. The electron beam machining diagram system typically consists of an electron gun, a beam focusing system, a vacuum system, and a power supply and control system.

. The vacuum system ensures that the beam travels through a low-pressure environment to prevent collisions with air molecules, which can scatter the electrons and reduce the machining accuracy. The power supply and control system regulates the beam current, voltage, and other parameters to achieve the desired machining conditions.

There are two main types of EBM processes: raster scanning and vector scanning. Raster scanning involves moving the beam back and forth over the workpiece in a series of parallel lines, while vector scanning involves moving the beam in a continuous path over the workpiece.

Compared to other machining techniques such as laser cutting or waterjet cutting, EBM offers a high level of precision and accuracy due to the focused electron beam. However, EBM also has some limitations, such as a relatively slow machining speed and a limited depth of cut.

Advantages of EBM

One of the main advantages of electron beam machining diagram is its high precision and accuracy, which makes it suitable for machining complex shapes and features with tight tolerances. Additionally, EBM has a low heat-affected zone (HAZ), which means that the surrounding material is not significantly affected by the machining process, reducing the risk of material distortion or damage.

EBM is also suitable for machining a wide range of materials, including metals, ceramics, composites, and semiconductors. This versatility makes EBM a useful tool in various industries, from aerospace to medical to electronics.

Another advantage of EBM is its cost-effectiveness and efficiency. Unlike traditional machining processes such as milling or drilling, EBM does not require physical contact with the workpiece, reducing tool wear and increasing the lifespan of the equipment. Additionally, EBM produces less waste material than other machining techniques, making it environmentally friendly.

Applications of EBM

The aerospace industry is one of the primary users of electron beam machining diagram, with applications such as machining turbine blades, jet engine components, and structural elements. EBM is also used in the medical industry for machining implants, prosthetics, and other medical devices with complex shapes and features.

The automotive industry uses EBM for tool and die making, as well as for prototyping and small-batch production of parts. In the electronics industry, EBM is used for machining microelectronic components and for repairing or modifying electronic circuits.

EBM also has applications in research and development, such as for machining prototypes or experimental components that require high precision and accuracy.

You can read this application of lvdt

EBM System Design and Optimization

The design and optimization of the EBM system are critical factors in achieving high machining performance and quality. The electron gun design and optimization can affect the beam current, energy, and spot size, which determine the machining accuracy and depth of the cut.

The beam-focusing system is also crucial for achieving a narrow and precise beam. This system typically consists of magnetic lenses that control the electron trajectory and focus the beam onto the workpiece.

The vacuum system is essential for maintaining a low-pressure environment and preventing air molecules from scattering the electrons. A high-quality vacuum system can improve the machining accuracy and reduce the risk of material contamination.

Finally, the power supply and control system regulates the beam current, voltage, and other parameters to achieve the desired machining conditions. These parameters can vary depending on the material properties, workpiece geometry, and other factors.

Challenges and Limitations of EBM

EBM also has some challenges and limitations that must be considered when using this machining process. One of the main limitations of EBM is its relatively slow machining speed, which can limit its use in high-volume production environments. Additionally, the electron beam machining diagram has a limited depth of cut compared to other machining techniques, which can make it unsuitable for certain applications.

Another challenge of EBM is the risk of material contamination. Because the machining process occurs in a vacuum environment, any residual gas or material can contaminate the workpiece, affecting its quality and performance.

Another limitation of EBM is its high initial equipment cost, which can be a barrier for smaller businesses or organizations. Additionally, the complexity of the EBM system and the need for specialized expertise can also make it challenging to implement and maintain.

You can read this type of micrometer

Conclusion

Electron beam machining is a high-precision machining process that offers numerous advantages for various industries, including aerospace, medical, automotive, and electronics. The EBM system consists of an electron gun, a beam focusing system, a vacuum system, and a power supply and control system.

EBM’s advantages include high precision and accuracy, low heat-affected zone, versatility in machining various materials, cost-effectiveness and efficiency, and environmental friendliness. However, EBM also has some limitations, including its slow machining speed, limited depth of cut, risk of material contamination, high initial equipment cost, and complexity.

Overall, EBM is a useful tool for achieving high-precision machining of complex shapes and features with tight tolerances. With proper system design and optimization, EBM can provide significant benefits for various applications in different industries.

FAQs

- Is EBM suitable for high-volume production environments?

- EBM’s relatively slow machining speed can limit its use in high-volume production environments.

- What materials can be machined using EBM?

- EBM is suitable for machining a wide range of materials, including metals, ceramics, composites, and semiconductors.

- How does EBM compare to other machining techniques such as laser cutting or waterjet cutting?

- EBM offers a high level of precision and accuracy due to the focused electron beam. However, it also has some limitations, such as a relatively slow machining speed and a limited depth of cut.

- What industries use EBM?

- EBM is used in various industries, including aerospace, medical, automotive, and electronics.

- What factors are critical for achieving high machining performance and quality in EBM?

- The design and optimization of the electron gun, beam focusing system, vacuum system, and power supply and control system are critical factors for achieving high machining performance and quality in EBM.

You can follow us on LinkedIn

I am a highly motivated and skilled individual with a passion for Electrical engineering. I have 1 year of experience in Robotics and Electrical engineering, which has allowed me to develop a strong set of skills in PLC, Painting Robots, SCADA. I am a quick learner and am always looking for new challenges and opportunities to expand my knowledge and skills. I am a team player and enjoy working with others to achieve a common goal. Successfully completed many projects for a various clients in the automobile sector.

Thank You