Introduction: Why Do PLC Programming Errors Matter?

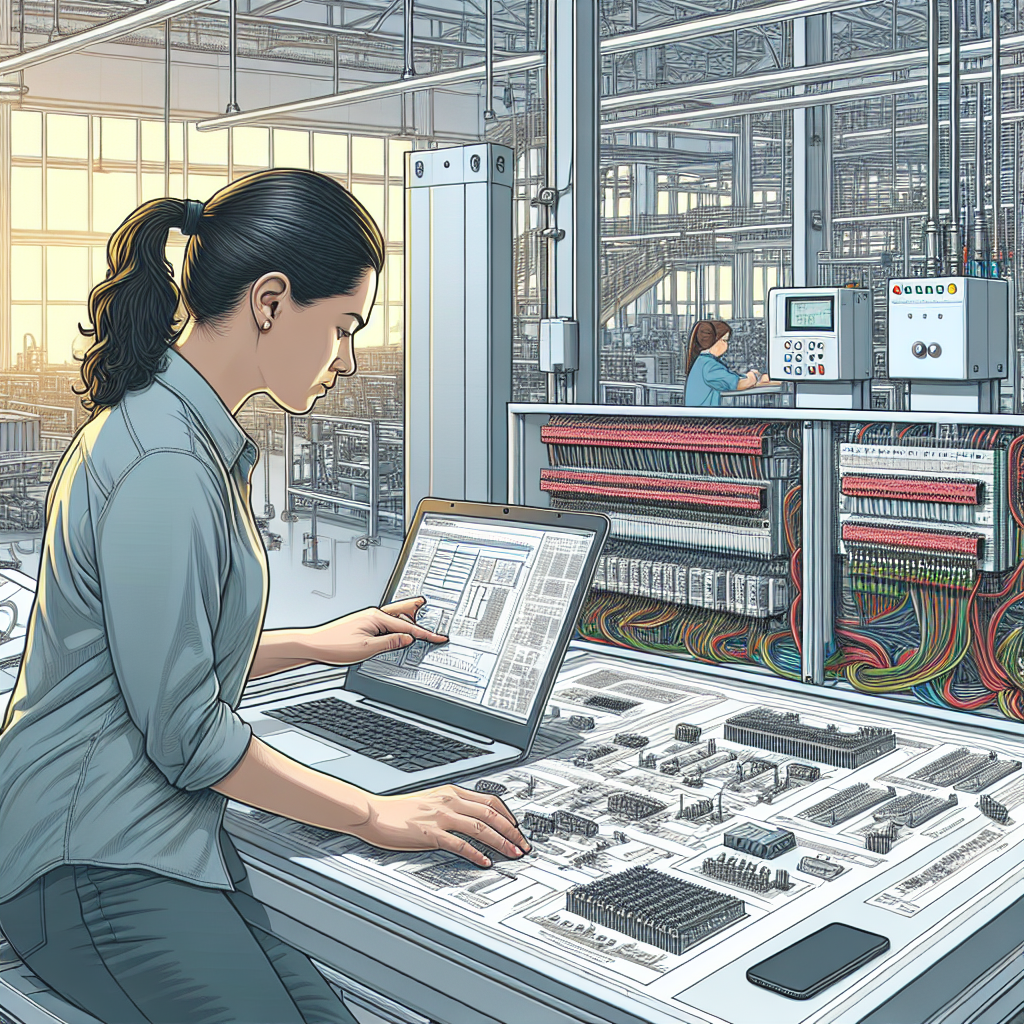

Picture this: It’s 2 AM on a Tuesday night, and you’re the only engineer on the plant floor. Suddenly, the line comes to a screeching halt. Alarms start blaring, and operators are giving you the look. The culprit? A pesky PLC programming error. This isn’t just a blip on the radar; this could mean thousands, if not tens of thousands, of dollars in lost production.

I’ve been there, staring at a console in the dim glow of the control cabinet lights, trying to decode a fault that’s bringing the whole operation to its knees. One time, I remember a simple forgotten semicolon in a Siemens S7-1200 program that took down a whole bottling line. It took hours to pinpoint, and believe me, those production managers weren’t happy.

Here’s the thing, PLC programming errors matter because they can cripple a facility. Addressing these errors promptly isn’t just important; it’s essential. Every second a machine is down, you’re losing money. Moreover, these errors can cascade, affecting other processes. So, getting on top of them quickly can save you a lot of sleepless nights—and face in front of your team.

Common Types of PLC Programming Errors

Syntax Errors

Syntax errors are like those annoying little typos in an email, but instead of a simple spelling mistake, you’re dealing with missing colons or mismatched parentheses. They’re the result of improper code structure and can prevent your PLC from even compiling. It’s like when you’re coding in RSLogix 5000 and you forget a parenthesis in a math function. The software will flag it immediately, but your program won’t run until it’s fixed.

I once spent a good chunk of a night trying to figure out why a Mitsubishi FX series PLC wouldn’t start a process. It turned out a simple ‘end’ statement was missing at the end of a subroutine. That’s right, one missing line, and you’ve got a whole system sitting idle.

Logic Errors

Now here’s where it gets interesting. Logic errors are the gremlins of the PLC world. These errors occur when your code runs without a hitch, but doesn’t behave as intended. I once wrote a routine for a Mitsubishi Q-series controller where an ‘if’ condition was accidentally inverted. Instead of stopping the conveyor when an item was detected, it started it. Talk about frustrating!

Pro Tip: Always peer-review logic with a colleague. Fresh eyes can catch what you might overlook.

In another instance, I had a ControlLogix program with a piece of logic that should’ve controlled a diverter valve. Due to a misaligned bit shift, the wrong valve was actuated, directing a whole batch of product to waste. That mistake cost a pretty penny and a long night fixing it.

Communication Errors

Communication errors can be a real headache, particularly when you’re wrangling with Modbus or Profinet networks. These networks are the lifelines of your PLCs. Imagine you’re dealing with a Modbus timeout on an Allen Bradley CompactLogix; it might just be a loose RS-485 terminal. I’ve spent hours tracing through Profinet cables only to find a single misplaced connector. These errors can be elusive, but they’re crucial to address since they can lead to data loss or miscommunication between devices.

Funny enough, I once worked a site where we spent days troubleshooting a network issue on a Siemens Profinet setup. It turned out a simple firmware mismatch between devices was causing all the confusion. Upgrading to the same version across the board resolved it instantly.

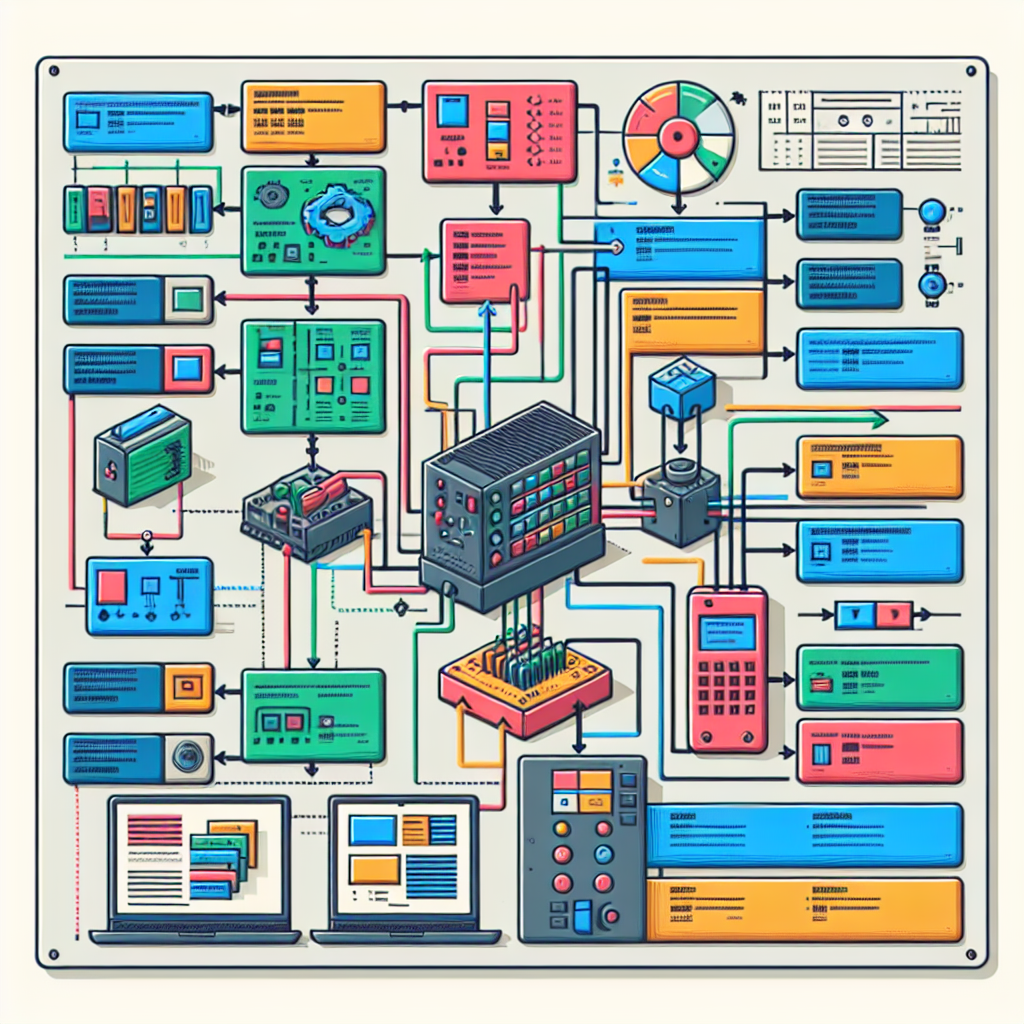

How to Identify and Troubleshoot PLC Errors

Using Diagnostic Tools

To effectively troubleshoot PLC programming errors, you’ll want to arm yourself with the right diagnostic tools. For Siemens PLCs, TIA Portal offers comprehensive diagnostics, while Allen Bradley’s RSLogix provides detailed error messages and troubleshooting steps. These tools are like your Swiss Army knife on the plant floor. They allow you to simulate and test your code, ensuring everything runs as expected before going live.

Pro Tip: Keep your software up to date. Tool updates often include new diagnostic features or bug fixes that can make your life easier.

Don’t forget about using network analyzers like Wireshark for communication issues. They can provide a real-time view of what’s happening on the network, which is invaluable for diagnosing those tricky Profinet or Ethernet/IP problems.

Reading Error Codes

Understanding error codes can make or break your troubleshooting process. Each error code is like a breadcrumb leading you to the root cause. For instance, a ‘F038’ on a Siemens S7-1500 typically indicates a communications error. Meanwhile, Allen Bradley might throw a ‘Code 16#0111’ for a logic issue. You should familiarize yourself with these codes, as they can drastically cut down your debugging time.

In one memorable case, a Mitsubishi PLC was throwing a mysterious error code that just wouldn’t go away. After a lot of digging, we found it was due to a corrupted memory card. Replacing the card resolved the issue, but it was the error code that first gave us a clue.

Analyzing Error Logs

Don’t underestimate the power of error logs. They’re like a diary of everything that went wrong. By analyzing these logs, you can often trace back to the exact moment an error occurred. For instance, if you notice repeated errors at the same time every day, it might indicate a scheduled task that’s misbehaving. Analyzing these logs in software like TIA Portal or RSLogix can provide insights that might not be immediately obvious.

For more tips on setting up error logs and using diagnostic tools, check out our guides on PLC Diagnostics.

Furthermore, tapping into external resources like Siemens’ support site can provide additional context and solutions from other professionals who’ve faced similar issues.

Common Mistakes to Avoid

Ignoring Warning Signs

Warnings exist for a reason. Often, we dismiss them as minor issues, but they can escalate into full-blown problems. For instance, a minor voltage spike warning on a VFD might not seem urgent, but it could point to a bigger issue like grounding problems. Ignoring it means risking a complete drive failure in the middle of production.

Skipping Documentation

You might think you’ll remember every change you made, but trust me, you won’t. Skipping documentation is a common mistake. It makes future troubleshooting an ordeal and can confuse team members who take over your project. Always document changes with as much detail as possible. Your future self will thank you.

Overlooking Small Errors

A small error can compound into a nightmare if left unchecked. I once saw a simple off-by-one error in array indexing that led to data corruption and nearly a day’s worth of lost production data. Address small errors immediately to avoid bigger headaches down the line.

Inadequate Training

I’ve met many engineers who jump into PLC programming without proper training. It’s like trying to drive a car without learning the pedals. Comprehensive training helps you understand the nuances of PLC programming, reducing the likelihood of errors and boosting your confidence.

Neglecting Regular Backups

Imagine losing a week’s worth of changes because of a system crash. It’s a nightmare. Regular backups are your safety net. Automate them if possible, but at the very least, perform manual backups at key milestones in your project. It’s a simple step that can save you from major headaches.

Best Practices for Avoiding PLC Programming Errors

Code Review and Testing

Let’s talk about code review. It’s your first line of defense against those pesky PLC programming errors. I’ve seen too many projects where skipping this step led to nightmare debugging sessions. Get another set of eyes on your work. You’ll be surprised what fresh perspectives can catch. Additionally, writing test cases for critical sections of your code can help ensure that changes don’t break existing functionalities. Trust me, spending a few minutes on this saves hours later.

In a particularly challenging project, I implemented a peer-review system where no code went live until at least one other engineer approved it. This simple change drastically reduced our error rate and improved the overall reliability of our systems.

Version Control

Ever deployed a change only to find it broke everything? You’re not alone. Version control systems like Git can prevent these headaches. They allow you to track changes and revert to stable versions when things go south. I personally prefer committing changes frequently with clear messages. It’s like a safety net, ensuring you don’t lose progress or introduce errors without a way back. If you’re not using version control for your PLC projects, you’re missing out on a lifesaver.

In one project, we used Git to manage a multi-location deployment across several plants. Having a single source of truth allowed us to synchronize updates seamlessly and roll back any problematic changes swiftly.

Regular Maintenance

Regular system checks and updates are often overlooked until something goes wrong. However, keeping your PLC systems updated with the latest firmware and software patches can prevent many errors. In my experience, most VFD faults, for instance, come down to parameter misconfiguration, which regular audits can easily catch. Schedule these checks into your maintenance routine, and you’ll find your systems running smoother.

I recall a time when a periodic check revealed a buildup of dust in a control panel that nearly caused a short. Simple cleaning prevented what could have been a massive downtime incident. Regular maintenance matters more than you might think!

Case Studies: Real-World PLC Error Resolutions

A Faulty Sensor Scenario

I once encountered a particular challenge with a faulty sensor on a packaging line. The sensor intermittently failed, causing unexpected stoppages. The real trick was figuring out that it wasn’t the sensor itself but the loose wiring causing false triggers. After securing the connections and replacing the sensor, the line ran smoothly. It hammered home the importance of checking physical connections before diving deep into the code.

Furthermore, I worked with a team to implement a redundancy check program that would alert us if the sensor readings fell outside expected parameters. This proactive approach helped us catch potential issues before they caused any downtime.

Network Latency Issues

Network latency can cause havoc, especially in time-sensitive applications. I recall a situation where a Profinet network operated sluggishly, delaying critical control commands. Upon investigation, we discovered the switch configuration did not prioritize the PLC traffic. By adjusting Quality of Service (QoS) settings, we managed to prioritize control data, resolving the latency issue. It’s a reminder that sometimes, the network configuration is just as critical as the code.

Moreover, a switch replacement with a more robust model, specifically designed for industrial environments, further improved our network’s reliability. Investing in quality network hardware pays off in the long run.

Frequently Asked Questions

What are the first steps to take when encountering a PLC error?

First, don’t panic. Start by identifying the error code and consult the manual for its meaning. Check recent changes in the code or physical setup. Ensure all connections are secure. This initial assessment can often pinpoint the issue or narrow down possibilities.

How can I improve my PLC troubleshooting skills?

Practice and study are your best friends here. Work on real-world projects and pay attention to experienced colleagues. Additionally, online courses and resources can offer structured learning. Dive into forums where professionals discuss challenges and solutions. The more you engage, the more you learn.

What tools are essential for diagnosing PLC errors?

You’ll want a good multimeter for electrical diagnostics and a laptop with the PLC programming software. Network analyzers are helpful for communication issues, and having access to the latest manuals and technical guides is invaluable. Don’t underestimate a well-organized toolbox and a clear mind.

How often should PLC systems be updated?

At a minimum, check for updates annually, but more frequent checks can be beneficial, especially for systems with known vulnerabilities. Apply updates during scheduled maintenance windows to minimize disruptions. Remember, keeping your system updated helps prevent known issues.

Why is version control important in PLC programming?

Version control acts as a safety net. It helps track changes, making it easy to identify where things went wrong. You can revert to a previous stable state if a new change causes issues. It’s invaluable for collaborative environments where multiple engineers may work on the same project.

Can network configuration affect PLC performance?

Absolutely. Network settings, such as Quality of Service (QoS), can prioritize traffic types, ensuring critical PLC commands aren’t delayed. Misconfigured networks can introduce latency, causing synchronization issues across systems. Regular audits of network configurations help maintain optimal performance.

Key Takeaways: Quick Reference for PLC Error Management

Addressing PLC programming errors quickly is crucial. Delays can lead to downtime or even damage. Essential tools and practices include code review, version control, and regular maintenance. Furthermore, continuous learning and adaptation keep you ahead of potential issues. Incorporate these strategies, and you’ll find yourself becoming more proficient and confident in managing PLC systems.

In conclusion, mastering PLC programming errors is all about vigilance, practice, and staying informed. Honestly, I think the effort you put into prevention and learning pays off massively. Don’t wait for the next breakdown—take action today. Share your experiences and tips in the comments section or on forums like industrialgyan.com, and let’s keep our systems running smoothly together.

I am an electrical & automation engineer with extensive experience in Design, PLC programming, SCADA development, and IoT integration. I have a strong background in the industry, focusing on the Design & Development of Hardware, Software &Industry 4.0 technologies, and the integration of intelligent manufacturing systems.

I have a deep understanding of electrical principles and am proficient in various programming languages, including Ladder Logic, Structured Text, and Python. In addition, I have experience with various PLC, SCADA & IoT technologies and a track record of successful integration projects for various clients.