Are you in the market for an insulator that can handle high-voltage power transmission? Look no further than the pin-type insulator. In this comprehensive guide, we will cover everything you need to know about this essential component in power line systems.

Introduction

Electricity is a crucial aspect of modern life. It powers our homes, businesses, and infrastructure, but it also presents some inherent risks. One of these risks is the potential for electric current to escape from its intended path and create a hazard. That’s where insulators come in. They help contain the flow of electricity and keep people and equipment safe. High-voltage power transmission systems commonly use the pin-type insulator as one of their most frequently used insulators. In this guide, we will explore what makes the pin-type insulator unique and what benefits it provides.

What is a Pin Type of Insulator?

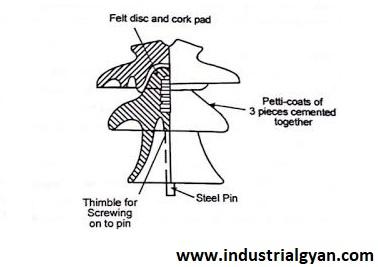

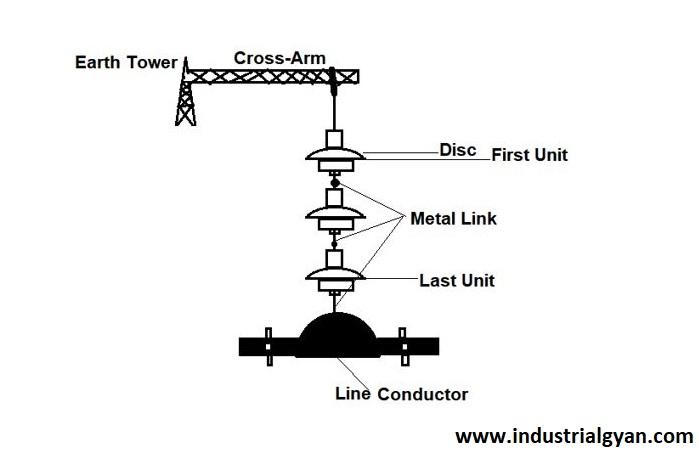

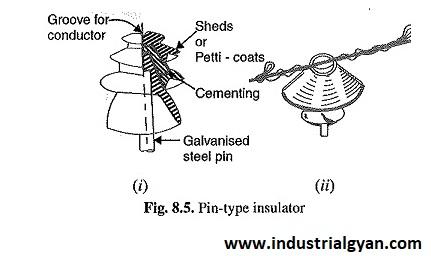

A pin-type insulators is a component in an overhead power line system that supports and insulates the conductive wires from the supporting structures. Manufacturers typically make this type of insulator from porcelain, glass, or polymer materials. The pin-type insulators have a cylindrical shape and feature a threaded stud that protrudes from the bottom end. Line workers use this stud to attach the insulator to the cross-arm of the supporting structure, which is usually a wooden or metal pole.

How Do a Pin Type Insulators Work?

The pin-type insulators work by preventing electric current from flowing from the conductive wire to the supporting structure. The insulator does this by creating a barrier of insulation between the two elements. When the insulator is properly installed, the conductive wire is suspended by the insulator, which isolates it from the structure and the ground. This allows electricity to flow safely and efficiently along the wires without creating a hazard.

Types of Pin Type Insulators

There are several different types of pin-type insulators, each designed for specific voltage and environmental conditions. The most common types include:

Solid Core Pin Type Insulators

The solid core pin type insulator is the most basic and commonly used type of pin type insulators. It consists of a solid ceramic core that is coated in an insulating glaze. This type of insulator is suitable for low to medium-voltage applications, typically up to 33 kV.

Suspension Pin Type Insulators

The suspension pin type insulators is designed for high-voltage power transmission applications. It features a hollow core that allows the insulator to support heavier conductive wires. The suspension pin type insulator is typically used in voltages ranging from 33 kV to 800 kV.

Long Rod Pin Type Insulator

The long rod pin type insulator is similar to the suspension pin type insulator, but it has a longer and thinner design. This type of insulator is typically used in areas with high levels of pollution, Transformer Parts diagram such as coastal regions or industrial areas. The long rod pin type insulator is suitable for voltage ranges up to 400 kV.

Polymer Pin Type Insulator

The polymer pin-type insulator is a more modern type of pin-type insulator. Manufacturers make the polymer pin-type insulator from materials like silicone rubber or epoxy to ensure superior resistance against harsh environmental conditions. They typically use it in areas with high pollution or extreme weather conditions, and it can handle voltages ranging from 10 kV to 500 kV.

Advantages of Pin Type Insulators

The pin-type insulator offers several advantages over other types of insulators, including:-

Superior Insulation

One of the main advantages of pin-type insulators is their superior insulation properties. The insulating material used in these insulators is highly resistant to electrical current, which allows them to provide effective insulation for high-voltage power transmission systems.

Easy Installation and Maintenance

Another advantage of pin-type insulators is their ease of installation and maintenance. The insulators can be easily installed onto the supporting structures using the threaded stud, and they require minimal maintenance over their lifetime.

Cost-Effective

Compared to other types of insulators, Pin type insulators cost less. Manufacturers typically use low-cost materials, like porcelain or glass, to make these insulators, which have a long lifespan and do not require frequent replacement.

Suitable for High Voltage Applications

Pin-type insulators are designed to handle high-voltage power transmission applications. They are capable of insulating conductive wires in voltage ranges up to 800 kV, which makes them ideal for use in high-voltage power transmission systems.

Pin Type Insulators Applications

The pin-type insulator is commonly used in power transmission systems around the world. Some of the most common applications include:

Overhead Power Lines

The pin-type insulators in overhead power lines support and insulate conductive wires. They typically install these insulators onto wooden or metal poles to prevent electrical current from flowing to the supporting structures.

Substations

Engineers use pin-type insulators in substations to support and insulate conductive wires. They usually install these insulators onto metal structures to stop the flow of electrical current to the ground.

Railways

pin-type insulators in railway systems to support and insulate conductive wires. They usually install these insulators onto metal structures to stop the flow of electrical current to the ground.

Pin Type Insulator FAQ

What is the lifespan of pin-type insulators?

Pin-type insulators typically have a lifespan of 25-30 years, but this can vary depending on the environmental conditions and the voltage level of the power transmission system. thermistor working principle

Do manufacturers commonly use which materials to make pin-type insulators?

The common materials used to make pin-type insulators include porcelain, glass, and polymer materials, such as silicone rubber or epoxy.

What is the difference between a solid core pin-type insulators and a suspension pin-type insulators?

The designers have designed the solid core pin type insulator for low to medium voltage applications, usually up to 33 kV. They have also designed suspension pin-type insulators for high-voltage power transmission applications, which typically range from 33 kV to 800 kV. The suspension pin type insulator also has a hollow core, which allows it to support heavier conductive wires.

What are the benefits of using polymer pin-type insulators?

Polymer pin-type insulators offer superior resistance to harsh environmental conditions, such as pollution or extreme weather, compared to traditional porcelain or glass insulators. They are also lighter and easier to handle during installation and maintenance.

How do you install pin-type insulators?

To install a pin-type insulator, an engineer attaches the threaded stud located on the bottom of the insulator to the cross-arm of the supporting structure. They then use a clamp or other attachment device to attach the conductive wire to the top end of the insulator.

How do you maintain pin-type insulators?

Pin-type insulators require minimal maintenance over their lifetime. Engineers should conduct periodic visual inspections to check for any signs of damage or wear in the insulator. If they identify any issues, they should replace the insulator immediately.

Conclusion

In conclusion, the pin-type insulators is a critical component of power transmission systems around the world. Its superior insulation properties, ease of installation and maintenance, cost-effectiveness, and suitability for high-voltage applications make it an ideal choice for a variety of power transmission applications. Whether you are building a new power transmission system or upgrading an existing one, the pin-type insulator is a reliable and effective choice that can help ensure the safe and efficient transmission of electrical power.

You can follow us on LinkedIn

I am a highly motivated and skilled individual with a passion for Electrical engineering. I have 1 year of experience in Robotics and Electrical engineering, which has allowed me to develop a strong set of skills in PLC, Painting Robots, SCADA. I am a quick learner and am always looking for new challenges and opportunities to expand my knowledge and skills. I am a team player and enjoy working with others to achieve a common goal. Successfully completed many projects for a various clients in the automobile sector.

Thank You