Introduction: The Real-World Automation Challenges

Industrial Automation can be a wild ride at times. Picture this: it’s 2 AM, the plant is humming along, and suddenly, everything comes to a screeching halt. I remember one such night when a Modbus network decided to throw a fit. We had boxes piling up, operators scratching their heads, and a supervisor who looked like he’d aged ten years in ten minutes. Not exactly how you want to spend your night.

In my experience, the most common issues in automation aren’t exotic gremlins. They’re the usual suspects: PLC programming woes, SCADA system glitches, and VFD headaches. Trust me, if you’ve spent any time on the plant floor, you know exactly what I’m talking about.

That’s why having strong troubleshooting skills is like gold. You need to know how to solve these problems quickly because, let’s face it, downtime is the enemy. And the reality is, these skills are honed over time, but a little guidance can save you from some of the more painful lessons.

PLC Programming Woes

Syntax Errors and Debugging

When it comes to Industrial Automation, PLC programming isn’t just about making things run; it’s about making them run right. Syntax errors are like those tiny stones in your shoe. Annoying, but fixable.

Take Siemens S7-1200 for example. A misplaced semicolon or a bracket can throw everything off. Once, I was helping a junior engineer who couldn’t figure out why his logic wasn’t working. Turns out, he had mixed data types in a math operation. Rookie mistake, but we’ve all been there. The real trick is keeping your eye on the details, and good documentation helps a lot.

Moreover, use the PLC’s built-in diagnostic tools to their full extent. Siemens TIA Portal has a great debugging environment. Use features like “Program Status” to see which instructions are being executed. Trust me, seeing the logic flow in real-time can be a lifesaver for spotting where things go astray.

Communication Failures

Then there are communication failures. These can be a real headache, especially with Allen Bradley PLCs. One time, I spent hours trying to figure out why a CompactLogix wasn’t talking to a PanelView HMI. The culprit? A misconfigured subnet mask. I can’t stress enough—double-check your IP settings. Trust me on this.

When you face these kinds of hiccups, get systematic. Check cables, confirm IP addresses, and verify network settings. If you’re still stuck, Rockwell’s knowledge base is a lifesaver. And don’t forget to keep your firmware up to date; it can resolve a lot of compatibility issues.

Additionally, consider using diagnostic tools like Rockwell’s RSLinx. This can help identify if the PLC can see the network but not specific devices. It’s a subtle difference, but knowing where the breakdown occurs can save hours of needless frustration.

SCADA System Challenges

Data Inconsistencies

Now, let’s talk SCADA. Data inconsistencies can make you want to pull your hair out. I once worked on a system where sensor data displayed on the SCADA was different from what’s recorded in the PLC. Turns out, the SCADA’s polling rate was too slow, causing misrepresentation. If you’re experiencing this, check your polling intervals and ensure your data types match across platforms.

Another important thing is to ensure synchronization settings are properly configured. In systems like Wonderware or Ignition, check your OPC server settings. A mismatch here can lead to data lags that are hard to trace back if you don’t know where to look.

User Interface Glitches

SCADA user interfaces can be another source of trouble. A sluggish UI can frustrate operators and slow down response times. One tip I swear by is optimizing graphic resolutions and minimizing animations. I once had a project where the HMI lagged, and simplifying the graphics did wonders. Also, make sure your SCADA server isn’t overloaded.

Pro Tip: Keep your SCADA database lean and clean. Avoid storing unnecessary historical data that can bog down performance.

From my experience, when commissioning SCADA systems, it’s crucial to perform end-to-end testing. I recall a commissioning job where everything seemed perfect until we went live and found a screen that didn’t update. It was because a tag was pointing to an old address. A comprehensive checklist can save you from these kinds of headaches.

VFD Configuration and Faults

Parameter Misconfigurations

VFDs are the workhorses of motors, but they’re not immune to quirks. Parameter misconfigurations are surprisingly common. I once had a client call me because their conveyor wouldn’t start, only to find that the acceleration time wasn’t set correctly. Simple fix, but a real showstopper if you don’t catch it right away.

Make sure to always check factory settings versus your application’s needs. Parameters like P001 or Pr.7 in different VFD models can mean the difference between smooth operation and a buzzing alarm. Additionally, the “Auto-tune” function is often overlooked but can dramatically improve performance if used correctly.

Overheating Issues

VFD overheating is another frequent headache. It can be due to poor ventilation or, believe it or not, a dusty environment. I had this issue on a processing line, and the fix was as simple as cleaning the cooling fans and ensuring adequate airflow. Check the ambient temperature ratings for your VFDs and make sure they’re installed in well-ventilated areas.

From my experience: Regular maintenance and cleaning can prevent most overheating issues. Set a schedule and stick to it.

I remember a particularly tricky situation where a misconfigured VFD led to a two-hour downtime. The motor wasn’t getting up to speed because someone had set the voltage boost too low. After some digging, we adjusted the parameters, and things ran smoothly. These experiences taught me to always double-check configurations before starting a shift.

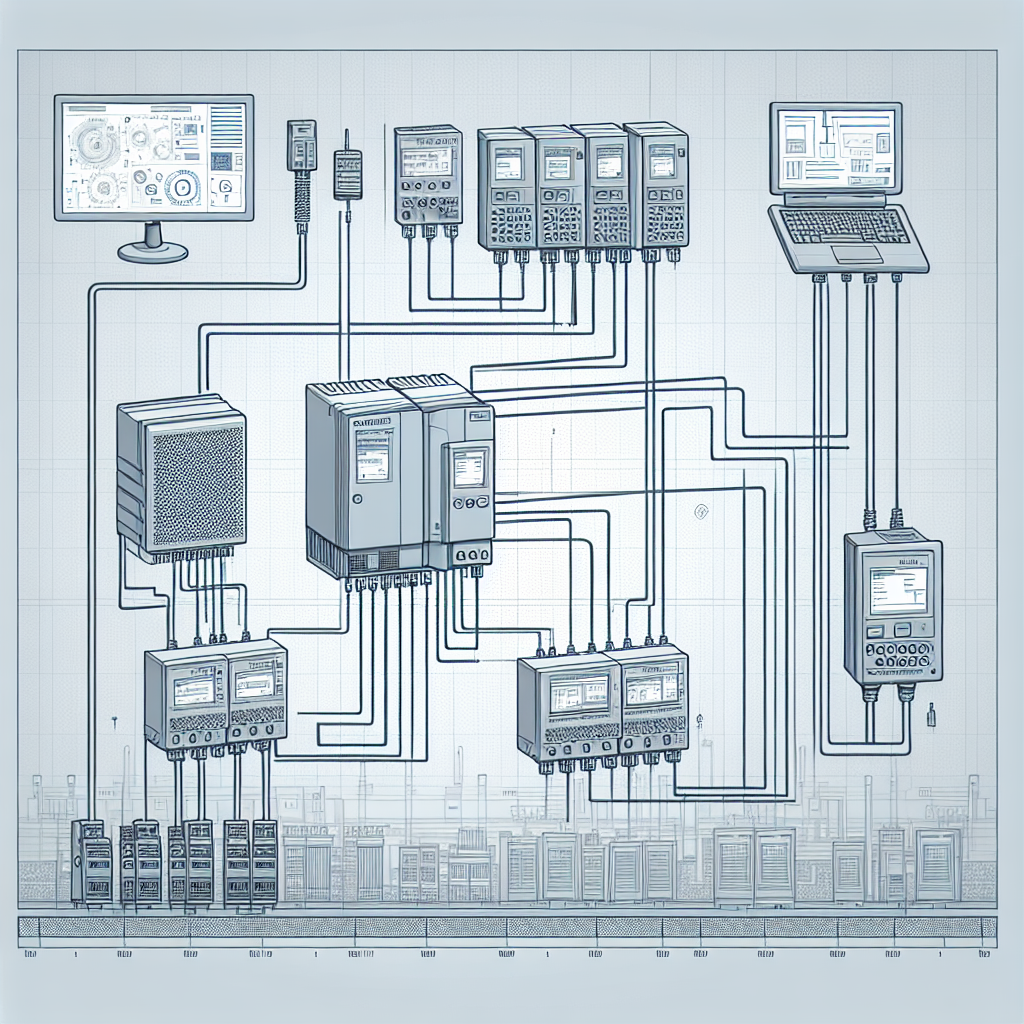

Networking Nightmares: Modbus and Profinet

Cable and Connector Issues

Networking in industrial automation can be its own beast. Cables and connectors often fly under the radar until they don’t. I’ve lost count of how many times a simple RJ45 or DB9 connector causes chaos. Make sure you’re using the right cable type, like Belden 9841 for RS-485 connections, and double-check your connectors. You’d be surprised how often a bent pin in a DB9 can bring your whole system to a halt.

Additionally, use cable testers regularly to ensure integrity. A tool like Fluke’s DSX-5000 can help you verify continuity and pin configuration, ensuring there’s no silent failure waiting to happen.

Network Timeout Troubleshooting

Now, let’s talk about those dreaded timeout errors. Modbus and Profinet each have their quirks. Modbus, for instance, is prone to issues with termination and biasing. A loose RS-485 terminal once had me tearing out hair for hours. Profinet, on the other hand, tends to struggle with IP address conflicts and subnet mismatches.

For Modbus, ensure your terminations are tight and your bias resistors are in place. Profinet usually needs a network scan to identify conflicts. Tools like Wireshark can be invaluable for detecting issues and diagnosing where things go wrong. Trust me, a little prep work can save a midnight callout.

Quick Tip: For Profinet, always validate your GSD files are up-to-date. This will minimize compatibility issues when adding new devices to your network.

Electrical Interference and Noise

Identifying Sources of Noise

Electrical noise can be a silent killer in automation systems. The real trick is identifying where it’s coming from. In my experience, most noise comes from power lines running too close to signal cables. Use a handheld noise meter to pinpoint these trouble spots. Once you know where it’s coming from, you’re halfway to fixing it.

Another source can be variable frequency drives (VFDs) themselves, which generate noise. If noise is an issue, consider investing in line reactors or filters. These can dramatically reduce harmonics and improve signal integrity.

Effective Shielding Techniques

Cable shielding is your best friend against noise. Use twisted pair cables with a foil shield, and always ground one end of the shield to avoid ground loops. I once saw a PLC behave erratically, only to find out the shield wasn’t grounded properly. A quick fix, but it could’ve been disastrous.

Keep your power and signal lines separate, and whenever possible, run signal cables in metal conduits. This not only shields them but also protects against physical damage. These small steps can mean the difference between smooth operations and hours of troubleshooting.

Common Mistakes to Avoid

- Neglecting Documentation: Look, I know it’s tedious, but not documenting changes is like shooting yourself in the foot. You won’t remember that IP change you made six months ago when something breaks, trust me.

- Skipping Software Updates: It’s tempting to skip updates, especially when everything’s running smoothly. However, outdated software is a ticking time bomb for security and compatibility issues.

- Improper Grounding: A poorly grounded system is an open invitation for electrical noise. Always verify that your grounding is solid.

- Overlooking Environmental Factors: Temperature, humidity, and dust can wreak havoc on electronic components. Make sure your system’s environment is within specified ranges.

- Ignoring Vendor Support: When all else fails, vendor support can be a lifesaver. Many engineers miss out on quick fixes by not reaching out to the experts.

Frequently Asked Questions

How do I troubleshoot a PLC that won’t communicate?

First, check your physical connections. Then, verify the IP settings and subnet mask. Make sure the PLC is not in a fault state. Finally, use a network diagnostics tool to check for communication packets and errors in the PLC software.

What’s the best way to configure a VFD?

Start by reading the motor nameplate and inputting those parameters into the VFD. Set your acceleration and deceleration times based on your application needs. Don’t forget to set the control source (local or remote). Always test the setup in a controlled environment before full operation.

How can I reduce noise in my network setup?

Ensure all cables are properly shielded and grounded. Separate power and signal cables as much as possible. Use surge protectors and line filters for sensitive equipment. Regularly inspect and maintain your network to catch any noise issues early.

What are common SCADA issues and fixes?

Common issues include data lag, incorrect data display, and alarms not triggering. Ensure your data paths are optimized, and regularly update your SCADA software. Check network connections and server loads if data display issues persist.

How do I identify parameter misconfigurations?

Perform a parameter check against the equipment’s manual settings. Use diagnostics tools provided by the equipment manufacturer to verify the current setup. It’s often a simple parameter that’s been overlooked, leading to operational hiccups.

Key Takeaways for Troubleshooting

Here’s a quick checklist to keep your automation issues at bay:

- Always double-check physical connections and network settings.

- Keep a spare parts inventory for cables and connectors.

- Regularly inspect and maintain shielding on all cables.

- Utilize network diagnostic tools to preemptively catch issues.

- Document changes meticulously to simplify future troubleshooting.

Regular maintenance is your best friend. It prevents many headaches down the line. Keep up with it, and you’ll save yourself countless hours.

Honestly, I think the most important advice I can give is to stay curious and never stop learning. Whether it’s a new PLC model or improved shielding techniques, there’s always something new out there. So, keep your eyes open and your toolkit ready. Your future self will thank you.

For more insights and tips on industrial automation, check out other articles on industrialgyan.com. If you’ve got your own stories or questions, feel free to drop a comment or reach out. Let’s make automation a little less daunting, one problem at a time!

I am an electrical & automation engineer with extensive experience in Design, PLC programming, SCADA development, and IoT integration. I have a strong background in the industry, focusing on the Design & Development of Hardware, Software &Industry 4.0 technologies, and the integration of intelligent manufacturing systems.

I have a deep understanding of electrical principles and am proficient in various programming languages, including Ladder Logic, Structured Text, and Python. In addition, I have experience with various PLC, SCADA & IoT technologies and a track record of successful integration projects for various clients.