Introduction

Electric motors play a crucial role in various industries and devices, powering everything from household appliances to heavy machinery. Within these motors, two key components, the stator, and rotor, work in harmony to generate mechanical energy from electrical energy. In this article, we will delve into the intricacies of stators and rotors, exploring their functions, working principles, differences, and importance.

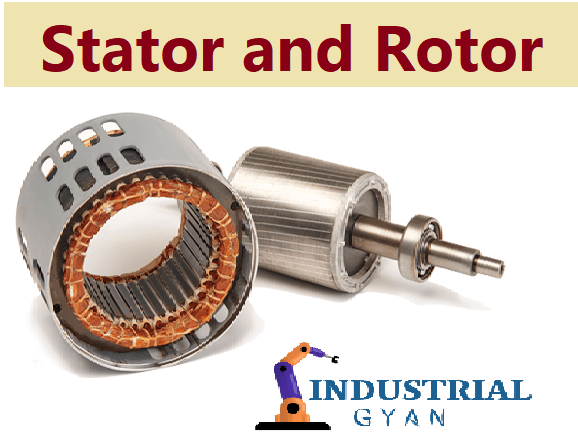

What is a Stator?

The stators is a stationary component in an electric motor that surrounds the rotor. It consists of a core made of laminated sheets and windings. The windings are typically made of copper or aluminum and are arranged in a specific pattern to create electromagnetic fields.

What is a Rotor?

On the other hand, the rotor is the moving part of the electric motor. It is located at the center of the stators and is connected to the motor’s output shaft. The rotor can be classified into two types: squirrel cage rotor and wound rotor. The squirrel cage rotor consists of conductive bars embedded in a laminated core, while the wound rotor contains windings similar to those found in the stators.

Stator and Rotor in Electric Motors

The stator and rotor work together to convert electrical energy into mechanical energy. When an electric current passes through the windings in the stator, it creates a rotating magnetic field. This magnetic field induces currents in the rotor, generating a force that causes the rotor to rotate. As a result, mechanical energy is produced, which can be used to drive various applications.

Working Principle of Stator and Rotor

The working principle of the stator and rotor revolves around electromagnetic fields. The stator windings receive alternating current, which generates a rotating magnetic field. This magnetic field interacts with the conductive bars or windings in the rotor, inducing currents. These currents create their own magnetic field, which interacts with the stator’s magnetic field, causing the rotor to rotate.

Differences Between Stator and Rotor

While the stator and rotor work together, they have distinct characteristics and functions. The stator remains stationary, while the rotor rotates. The stator creates the rotating magnetic field, while the rotor responds to the magnetic field and converts it into mechanical energy. Furthermore, the stator consists of windings, whereas the rotor may have conductive bars or windings, depending on its type.

Importance of Stator and Rotor

The stator and rotor are vital components in electric motors, enabling the conversion of electrical energy into mechanical energy. They form the foundation of motor functionality and efficiency. The design and quality of the stator and rotor directly impact the motor’s performance, reliability, and longevity. Therefore, manufacturers and engineers pay great attention to optimizing these components to achieve optimal motor performance.

Applications of Stator and Rotor

Stators and rotors find applications in a wide range of industries and devices. Electric motors utilizing stators and rotors power various equipment, including pumps, fans, compressors, conveyor belts, automobiles, and even aircraft. Their versatility and ability to convert electrical energy into mechanical energy make them indispensable in modern technology.

Maintenance and Care for Stator and Rotor

To ensure the longevity and optimal performance of stators and rotors, proper maintenance and care are essential. Regular inspections, cleaning, and lubrication of the motor components help prevent issues such as overheating and excessive wear. Additionally, monitoring electrical parameters and addressing any abnormalities promptly can mitigate potential damage to the stator and rotor.

Common Issues with Stators and Rotors

Despite their importance, stators and rotors may encounter certain issues over time. Some common problems include electrical shorts, insulation breakdown, bearing failure, and mechanical misalignment. These issues can lead to motor inefficiencies, increased energy consumption, and even motor failure. Timely detection and troubleshooting can help mitigate these problems.

Troubleshooting Tips

When facing issues with stators and rotors, a systematic troubleshooting approach can be beneficial. Start by inspecting the electrical connections, windings, and insulation for any visible signs of damage. Utilizing diagnostic tools such as multimeters and thermal cameras can aid in identifying hidden issues. Consulting the motor manufacturer’s guidelines and seeking professional assistance can provide further guidance in resolving complex problems.

Conclusion

In conclusion, the stators and rotors are integral components of electric motors, working together to convert electrical energy into mechanical energy. The stator creates a rotating magnetic field, while the rotor responds to the magnetic field and generates motion. Understanding the functions, working principles, and maintenance requirements of stators and rotors is crucial for ensuring the optimal performance and reliability of electric motors.

FAQ

Q1. What is the main difference between the stators and rotors? The main difference is that the stators remain stationary, while the rotor rotates.

Q2. Can the stator and rotor be made of different materials? Yes, the stator and rotors can be made of different materials depending on the motor’s design and requirements. Common materials include laminated sheets, copper, and aluminum.

Q3. Are stators and rotors used only in electric motors? Yes, stators and rotors are primarily used in electric motors, but they can also be found in other devices such as generators and alternators.

Q4. How often should stators and rotors be inspected? Regular inspections are recommended, especially during routine maintenance schedules. The frequency may vary depending on the motor’s operating conditions and usage.

Q5. Can issues with stators and rotors be repaired? In some cases, issues with stators and rotors can be repaired, especially if they are minor. However, severe damage or failure may require replacement of the affected components.

You can follow us on LinkedIn

Also, Learn About Slip Ring Induction Motor

I am an electrical & automation engineer with extensive experience in Design, PLC programming, SCADA development, and IoT integration. I have a strong background in the industry, focusing on the Design & Development of Hardware, Software &Industry 4.0 technologies, and the integration of intelligent manufacturing systems.

I have a deep understanding of electrical principles and am proficient in various programming languages, including Ladder Logic, Structured Text, and Python. In addition, I have experience with various PLC, SCADA & IoT technologies and a track record of successful integration projects for various clients.