Introduction: Setting the Stage for PLC Troubleshooting

You know, there was a night I remember vividly. It was 2 AM, and I was knee-deep in a production emergency. The plant was down, and the PLCs were refusing to cooperate. I spent hours combing through the system, only to find a loose terminal. It was a simple fix but a powerful reminder of the complexity of PLC troubleshooting.

PLCs, or Programmable Logic Controllers, are the heartbeat of industrial automation. They control everything from conveyor belts to robotic arms. However, when they falter, they can bring entire operations to a standstill. Engineers often wrestle with issues like unexpected shutdowns, communication errors, and misbehaving I/O modules.

In this article, I’m going to walk you through the practical strategies I’ve gathered over my 15+ years on the plant floor. Trust me, these aren’t just textbook tips. They’re hard-earned lessons from late nights and early mornings spent troubleshooting PLCs.

Understanding the Basics of PLC Circuits

Components of a PLC Circuit

Before diving into troubleshooting, let’s get familiar with the essentials of a PLC circuit. You’ll typically find a CPU, I/O modules, and a power supply. The CPU is the brain, executing the logic you’ve programmed. Meanwhile, I/O modules act as the eyes and ears, interfacing directly with sensors and actuators. A Siemens S7-1200, for example, comes with a compact design but powerful processing capabilities that suit various applications.

In my experience, the choice of I/O modules can make or break a system’s reliability. For instance, using high-density modules in a humid environment without proper enclosure can lead to corrosion and intermittent failures. Always consider environmental factors when choosing your components.

PLC troubleshooting – technical diagram and overview

How PLCs Interact with Other Systems

Think of PLCs as conductors in an orchestra, managing inputs from sensors like proximity switches and outputs to devices like motors. These components communicate through various protocols, with Profinet and Modbus being common in many setups. Understanding these interactions is crucial in effective PLC troubleshooting.

For instance, a basic circuit might involve a sensor detecting a product on a conveyor, which sends a signal to the PLC. The PLC processes this input and signals an actuator to stop the conveyor until the product is removed. It’s this interplay of components that forms the backbone of industrial automation.

I remember one site where the integration of an RFID system with a PLC was causing so much headache. The issue was a misconfigured baud rate between the RFID reader and the PLC’s communication module. Tweaking those settings resolved the communication error, but it taught me a lot about the nuances of protocol configurations.

Common PLC Circuit Problems and Their Causes

Power Supply Issues

One of the first things to check during PLC troubleshooting is the power supply. Symptoms of a failing power supply include erratic behavior or complete system shutdowns. If your PLC isn’t powering up, it’s a good idea to measure the voltage with a multimeter. You should see a stable 24V DC in most systems.

Funny enough, I once found a faulty power supply caused by a simple blown fuse. Replacing it resolved the issue, but it was a solid reminder to always check the basics before diving into complex diagnostics.

I/O Module Failures

I/O modules are another common point of failure. If your inputs or outputs aren’t responding as expected, you might be dealing with a faulty module. Look for blown fuses or damaged connectors. I once had a problem where a single faulty I/O module caused an entire line to halt. Swapping it out resolved the issue.

Moreover, always keep spare I/O modules handy. It can save you loads of time during critical failures. I usually recommend carrying spares for the most failure-prone modules based on historical data.

Communication Errors

Communication errors are a frequent headache in PLC troubleshooting. Networks like Profinet and Modbus can suffer from noise interference, loose connections, or misconfigurations. Check your network cables and connectors first. Funny enough, I once spent hours chasing a phantom fault that ended up being a loose RJ45 connection.

Another time, I dealt with a persistent Modbus communication error. After countless attempts at reconfiguring the settings, it turned out to be a faulty DB9 connector. Swapping it out brought the system back to life.

Effective Troubleshooting Techniques

Step-by-Step Troubleshooting Process

Successful PLC troubleshooting starts with a logical approach. Begin by identifying the symptoms and isolating the problem. Break down the process into steps: check power, examine connections, then move to I/O modules and software.

Pro Tip: Keep a checklist handy. It ensures you don’t miss critical steps, especially when time’s tight.

Always start with the basics: power supply, connections, and configurations. Once you rule out the simple issues, dig deeper.

Tools and Equipment You’ll Need

Equip yourself with the right tools: multimeters, oscilloscopes, and screwdrivers are essentials. These help you measure voltages, check signal integrity, and tighten any loose connections.

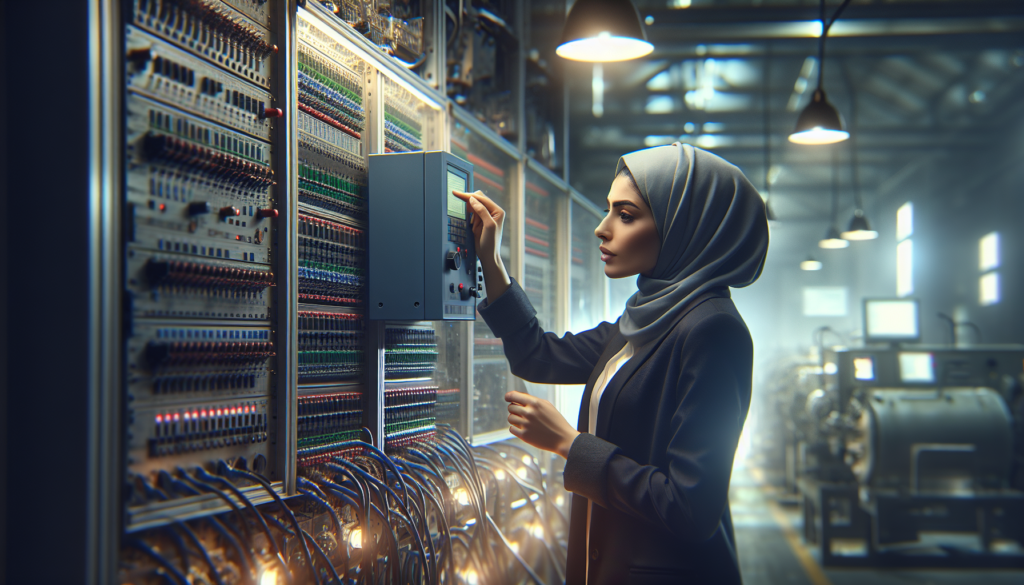

PLC troubleshooting – practical illustration and example

Documenting issues is just as important. Maintain a log of problems and solutions. This practice not only helps in future troubleshooting but can also be a lifesaver when you’re trying to explain recurring issues to management.

Additionally, having a laptop with the necessary PLC programming software, like TIA Portal for Siemens or RSLogix 5000 for Allen Bradley, is crucial for diagnosing software-related issues.

Advanced Troubleshooting: Tackling Complex Issues

Firmware and Software-Related Issues

Firmware updates can fix bugs and introduce new features, but they also come with risks. Always back up your configurations before updating. If a PLC behaves unpredictably after a firmware update, consider rolling back to the previous version.

Look, not every update is essential. Review the release notes carefully and decide if the benefits outweigh the risks. This thought process has saved me from unnecessary headaches multiple times.

Dealing with Intermittent Faults

Intermittent faults are the bane of PLC troubleshooting. They’re like ghosts—hard to catch but disruptive. Use data logging tools to monitor system behavior over time. I once resolved an intermittent issue by analyzing logged data, which revealed a pattern related to temperature fluctuations.

For an in-depth read on the importance of PLC data logging, check out our detailed article.

Also, consider using diagnostic tools that can simulate various conditions to help isolate the problem.

Common Mistakes to Avoid

Look, we all make mistakes. But in PLC troubleshooting, some are more common—and more avoidable—than others. Let’s go over a few I’ve seen too many times.

Ignoring the Basics

It’s easy to overlook the simple stuff when you’re in a rush. Always start with power checks and visual inspections. Trust me, you’ll save time in the long run.

Not Keeping Documentation

Skipping documentation is a rookie mistake. Not only does it help you notice patterns, but it’s also invaluable when handing over to another engineer or dealing with recurring issues.

Overlooking Firmware Updates

Firmware updates often improve functionality and fix bugs. Ignoring these can leave you with unresolved issues. However, always back up before updating.

Neglecting Component Compatibility

Mixing components from different manufacturers without checking compatibility can lead to unexpected errors. Always refer to compatibility charts or consult with the suppliers.

Underestimating Environmental Factors

Heat, dust, and moisture are silent killers. Ensure your PLCs are in environments that meet their specified conditions to avoid erratic behavior or failure.

Preventive Measures to Minimize Future Problems

Routine Maintenance

Preventive maintenance can save you from unplanned downtime. Schedule regular checks on your PLC systems, focusing on cleaning, inspecting connections, and testing power supplies.

Furthermore, keep an eye on hardware diagnostics. Many modern PLCs offer built-in diagnostics that can preemptively warn you about potential issues.

Upgrading Components

While routine maintenance helps, sometimes you need to consider upgrades. Components wear out over time, and newer technology might offer greater efficiency and reliability. Keep an eye on the lifecycle of your PLC components and plan upgrades accordingly.

In addition, adopting best practices like proper cable management and avoiding environments with high dust can significantly extend the life of your equipment.

Frequently Asked Questions

Why is my PLC not responding to inputs?

There could be several reasons: a faulty I/O module, incorrect wiring, or a configuration issue in the PLC program. Start by checking the hardware connections, then verify the software configuration.

How can I prevent PLC communication errors?

Ensure that all network cables are secure and in good condition. Use shielded cables to minimize electrical noise, and regularly check network settings to catch any misconfigurations early.

What tools are essential for PLC troubleshooting?

You’ll need a multimeter, an oscilloscope, a set of screwdrivers, and possibly a network tester. These tools help you diagnose electrical and communication issues effectively.

When should I replace my PLC?

Consider replacing your PLC when it becomes unreliable, repairs are frequent, or you need more processing power for modern applications. Evaluating the cost of repairs versus a new system is crucial.

How do I handle software issues on a PLC?

Software issues often arise from incorrect configurations or outdated firmware. Always back up your settings before making changes, and consult the manufacturer’s guidelines for updates.

Can environmental conditions affect PLC performance?

Absolutely. Factors like temperature, humidity, and dust can affect performance. Ensure your PLCs are housed in conditions suitable to their specifications to mitigate these risks.

How often should I perform preventive maintenance?

It depends on your plant’s operational demands, but a quarterly check is a good starting point. Adjust based on readings and past maintenance records.

What should I do if I suspect a power supply issue?

Check the voltage and current output with a multimeter. If the values are unstable, replace the power supply unit. Inspect the power cables for any signs of wear or damage.

How can I deal with intermittent faults effectively?

Use data logging to identify patterns. Monitor environmental conditions like temperature and humidity, as they may correlate with the faults. Persistent data analysis often unveils the root causes.

Key Takeaways for Effective PLC Troubleshooting

Let’s wrap this up. When it comes to PLC troubleshooting, a methodical approach is your best friend. Identify the problem, isolate issues, and use the right tools. Document everything, because patterns emerge over time.

Don’t forget preventive measures. They can dramatically reduce downtime and prolong your system’s life. And keep learning; technology evolves, and so should you.

So here’s my final thought: embrace the challenges, learn from each one, and share your knowledge. The next time you’re in the plant canteen, pass on a tip. You never know who’s listening and who might avoid a late-night troubleshooting session because of it.

I am an electrical & automation engineer with extensive experience in Design, PLC programming, SCADA development, and IoT integration. I have a strong background in the industry, focusing on the Design & Development of Hardware, Software &Industry 4.0 technologies, and the integration of intelligent manufacturing systems.

I have a deep understanding of electrical principles and am proficient in various programming languages, including Ladder Logic, Structured Text, and Python. In addition, I have experience with various PLC, SCADA & IoT technologies and a track record of successful integration projects for various clients.