Micrometers are precision measuring instruments used to measure the dimensions of various objects with high accuracy. In engineering, machining, and manufacturing industries, people commonly use them to ensure that the produced components meet the required specifications. There are different types of micrometers available in the market, each designed for a specific purpose. In this article, we will discuss the different types of micrometers and their applications. with a specific type of micrometer.

Introduction to Micrometers

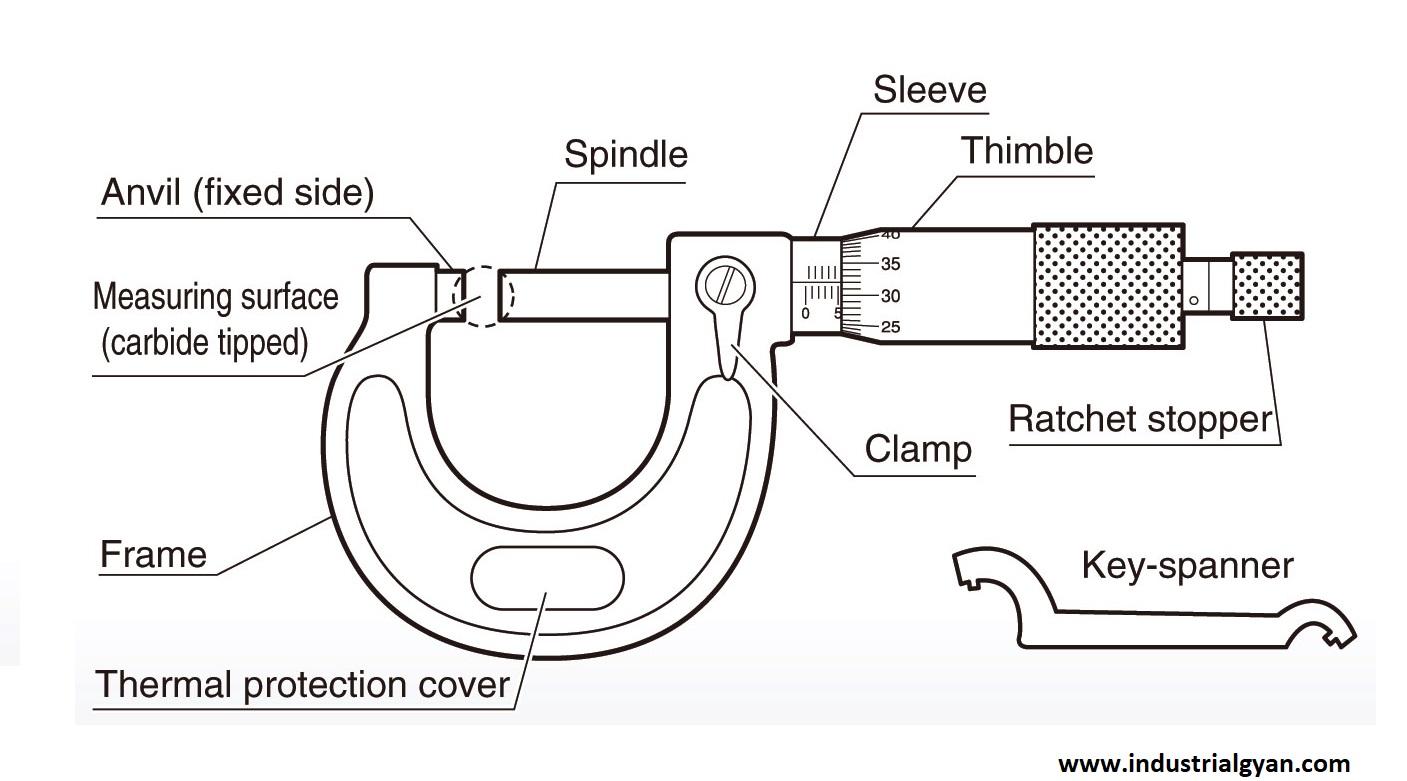

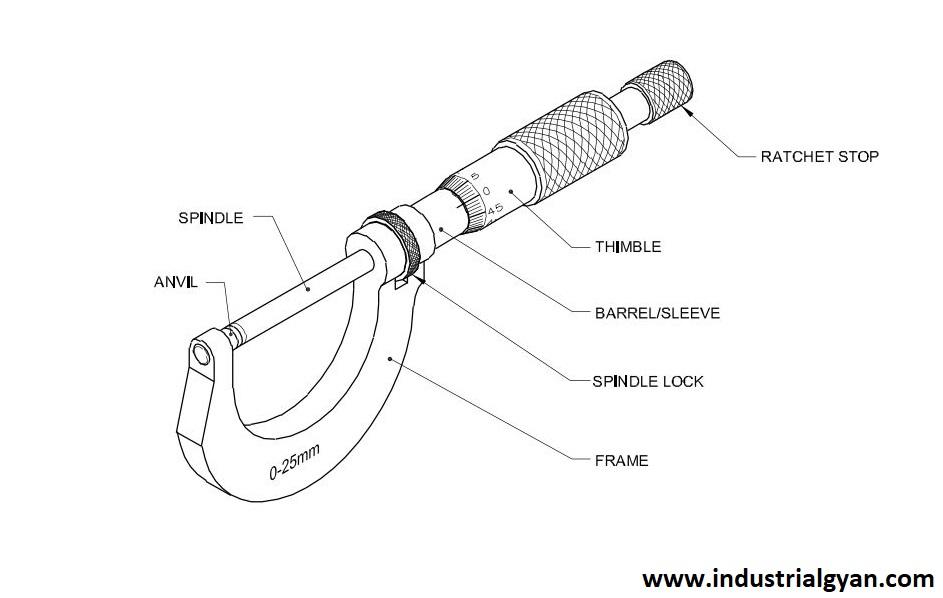

Micrometers are precise instruments used to measure the dimensions of objects. They consist of a frame, an anvil, a spindle, and a thimble. The anvil is a stationary flat surface, while the spindle is a moving component that measures the distance between the anvil and itself.

During measurement, the spindle contacts the object being measured with its measuring face, and the thimble, which is connected to the spindle, is employed for taking measurements.

Type of Micrometer

Outside Micrometer

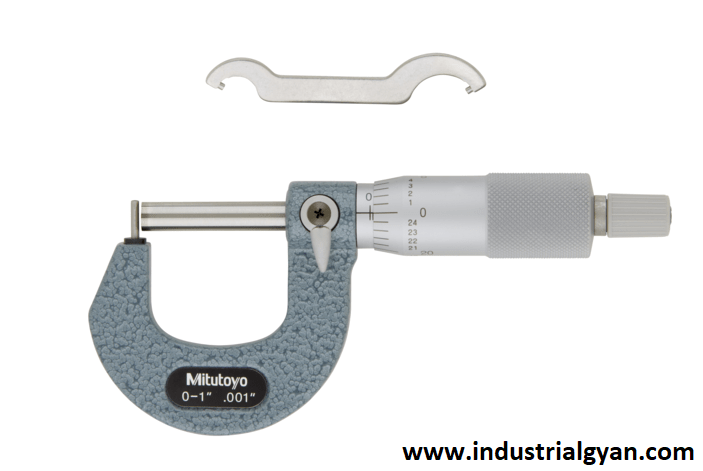

The outside micrometer, also known as a micrometer screw gauge, is used to measure the external dimensions of an object. It consists of a C-shaped frame with a screw mechanism that moves the spindle towards or away from the anvil. The spindle has a flat measuring face that comes into contact with the object being measured. Outside micrometers are available in different sizes, ranging from 0 to 300 mm.

Inside Micrometer

The inside micrometer is used to measure the internal dimensions of an object, such as the diameter of a hole. It consists of a C-shaped frame with two measuring faces, one fixed and one movable. The movable measuring face is attached to a screw mechanism that moves it towards or away from the fixed measuring face. Inside micrometers are available in different sizes, ranging from 5 to 150 mm.

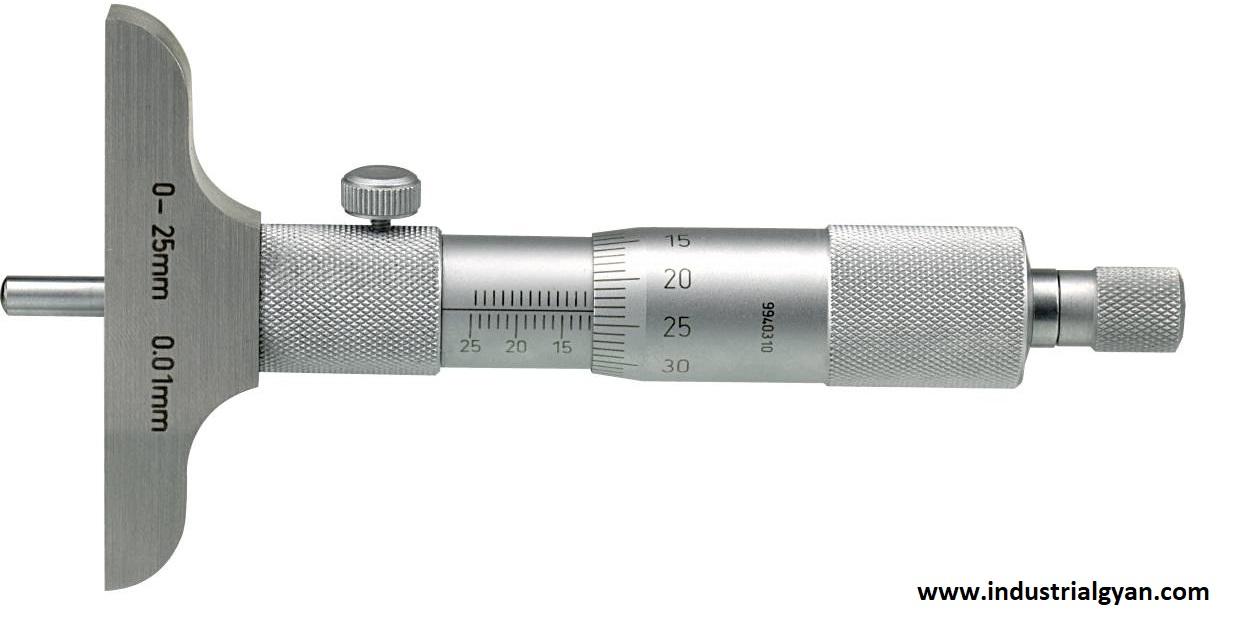

Depth Micrometer

The depth micrometer is used to measure the depth of holes, slots, and recesses. It consists of a C-shaped frame with a measuring rod attached to the spindle. The measuring rod can be extended or retracted to measure the depth of the object being measured. Depth micrometers are available in different sizes, ranging from 0 to 150 mm.

Thread Micrometer

The thread micrometer is used to measure the pitch diameter of screw threads. It consists of a C-shaped frame with a V-shaped measuring face that comes into contact with the screw thread. The spindle is attached to a screw mechanism that moves it towards or away from the anvil. Thread micrometers are available in different sizes, ranging from 0 to 25 mm.

Blade Micrometer

A blade micrometer is a precision tool that finds its application in measuring the thickness of thin objects, such as sheets of paper or metal foils. It consists of a C-shaped frame with a flat measuring face that makes contact with the object being measured. Furthermore, a blade is connected to the measuring face, which allows for the measurement of various thicknesses by adjusting it.

Pitch Micrometer

A pitch micrometer is a specialized tool used to measure the pitch of gear teeth or screw threads. It has a C-shaped frame with a V-shaped measuring face that contacts the object being measured. Moreover, the spindle attaches to a screw mechanism that moves it towards or away from the anvil. Pitch micrometers are available in different sizes, ranging from 0 to 25 mm.

Digital Micrometer

The digital micrometer is an electronic micrometer that provides digital readings of the dimensions being measured. It consists of a C-shaped frame with a digital display that shows the measurements. The spindle is attached to a screw mechanism that moves it towards or away from the anvil. Digital micrometers are available in different sizes, ranging from 0 to 300 mm.

Vernier Micrometer

The vernier micrometer is a vital mechanical micrometer that offers accurate readings of the dimensions being measured. It has a C-shaped frame that incorporates a vernier scale for precise measurement reading. Additionally, the spindle attaches to a screw mechanism that moves it towards or away from the anvil. Furthermore, vernier micrometers come in different sizes, ranging from 0 to 300 mm.

Dial Micrometer

The dial micrometer is a mechanical micrometer that provides readings of the dimensions being measured on a dial. It consists of a C-shaped frame with a dial that shows the measurements. The spindle is attached to a screw mechanism that moves it towards or away from the anvil. Dial micrometers are available in different sizes, ranging from 0 to 300 mm.

Tube Micrometer

It has a C-shaped frame with a V-shaped measuring face that contacts the object being measured. The spindle attaches to a screw mechanism that moves it towards or away from the anvil. Moreover, tube micrometers come in different sizes, ranging from 0 to 150 mm.

You can also read this braking resistor

Point Micrometer

The point micrometer is used to measure the diameter of small objects, such as wires and rods. It consists of a C-shaped frame with two pointed measuring faces, one fixed and one movable. The movable measuring face is attached to a screw mechanism that moves it towards or away from the fixed measuring face. Point micrometers are available in different sizes, ranging from 0 to 25 mm. This is a special type of micrometer.

Micrometer Caliper

The micrometer caliper is a combination of a micrometer and a caliper. It can measure both internal and external dimensions, as well as depth and thickness. It consists of a C-shaped frame with a measuring rod attached to the spindle. The measuring rod can be extended or retracted to measure different dimensions. Micrometer calipers are available in different sizes, ranging from 0 to 150 mm.

Spline Micrometer

The spline micrometer is an essential tool used for measuring the dimensions of splines and gears. It has a C-shaped frame with a V-shaped measuring face that contacts the object being measured. The spindle attaches to a screw mechanism that moves it towards or away from the anvil. Additionally, spline micrometers come in different sizes, ranging from 0 to 150 mm. Consequently, they are a crucial type of micrometer for many industries.

Multi-Anvil Micrometer

The multi-anvil micrometer measures the thickness of objects with multiple surfaces, such as parallelism or thickness of gaskets, washers, or parts with steps. It includes a C-shaped frame with multiple anvils, and each anvil has a flat measuring face that contacts the object being measured. The user can adjust the anvils to measure different surfaces. Multi-anvil micrometers are available in different sizes, ranging from 0 to 25 mm. This is a special type of micrometer.

Bore Micrometer

The bore micrometer is used to measure the diameter of holes or bores. It consists of a C-shaped frame with two pointed measuring faces, one fixed and one movable. The movable measuring face is attached to a screw mechanism that moves it towards or away from the fixed measuring face. Bore micrometers are available in different sizes, ranging from 4 to 1600 mm.

Hottest Micrometer

The hottest micrometer measures the internal diameter of bores or tubes. It has a C-shaped frame with a measuring face that expands to fit the internal diameter of the object being measured. A screw mechanism attaches the measuring face and moves it towards or away from the anvil. The user can find the hottest micrometers in different sizes, ranging from 2 to 300 mm.

Conclusion

Micrometers are precision measuring tools that are used to measure dimensions accurately. There are various types of micrometers available, each designed to measure specific dimensions or types of objects. Understanding the different types of micrometers and their applications can help you choose the right one for your measurement needs.

You can also read this classification of transducer

FAQs

- What is the accuracy of a micrometer?

- Micrometers can provide accuracy up to 0.001 mm or even better, depending on the type and quality of the instrument.

- How do you use a micrometer?

- To use a micrometer, place the object being measured between the spindle and the anvil and tighten the thimble until the object is held securely. Then, read the measurement on the micrometer scale or digital display.

- What is a digital micrometer used for?

- A digital micrometer is used to provide digital readings of the dimensions being measured. It is useful for applications that require high accuracy and precision. This is a very high-demanding type of micrometer.

- How do you calibrate a micrometer?

- To calibrate a micrometer, use a calibration standard that is traceable to a national or international standard. Place the calibration standard between the spindle and the anvil and adjust the micrometer until it reads the correct value.

- Can micrometers measure angles?

- No, micrometers are not designed to measure angles. They are designed to measure dimensions such as length, thickness, and diameter.

You can follow us on LinkedIn

I am a highly motivated and skilled individual with a passion for Electrical engineering. I have 1 year of experience in Robotics and Electrical engineering, which has allowed me to develop a strong set of skills in PLC, Painting Robots, SCADA. I am a quick learner and am always looking for new challenges and opportunities to expand my knowledge and skills. I am a team player and enjoy working with others to achieve a common goal. Successfully completed many projects for a various clients in the automobile sector.

Thank You