Introduction

Silicon Controlled Rectifiers (SCRs) are semiconductor devices widely used in various electrical applications, from power supplies to motor control. Understanding the VI characteristics of SCR is crucial for engineers and technicians working with these devices. In this article, we will delve into the behavior of SCRs, exploring their voltage-current relationship and shedding light on their important parameters and operating regions.

Table of Contents

- Introduction to SCRs

- What are VI Characteristics?

- The Basics of SCR Operation

- Forward Blocking Region

- Forward Conduction Region

- Forward Voltage Drop

- Holding Current and Latching Current

- Reverse Blocking Region

- Gate Triggering

- Gate Triggering Methods

- Turn-off Process

- Commutation and Snubber Circuits

- Protection and Heat Dissipation

- Applications of SCRs

- Conclusion

1. Introduction to SCRs

SCRs, also known as thyristors, are four-layer solid-state devices capable of controlling large amounts of electric power. They are widely used in electronic circuits requiring high-voltage and high-current switching capabilities.

2. What are VI Characteristics?

VI characteristics, short for voltage-current characteristics, describe the behavior of an electronic component in response to varying voltage and current levels. They provide insights into how the component behaves under different operating conditions.

3. The Basics of SCR Operation

SCRs have three main terminals: an anode, a cathode, and a gate. When a positive voltage is applied to the gate with respect to the cathode, the SCR enters a conductive state, allowing current flow from the anode to the cathode.

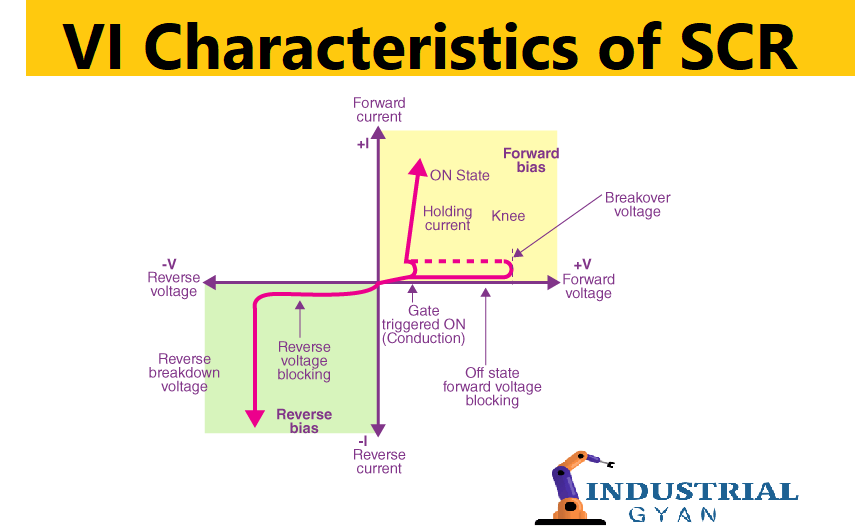

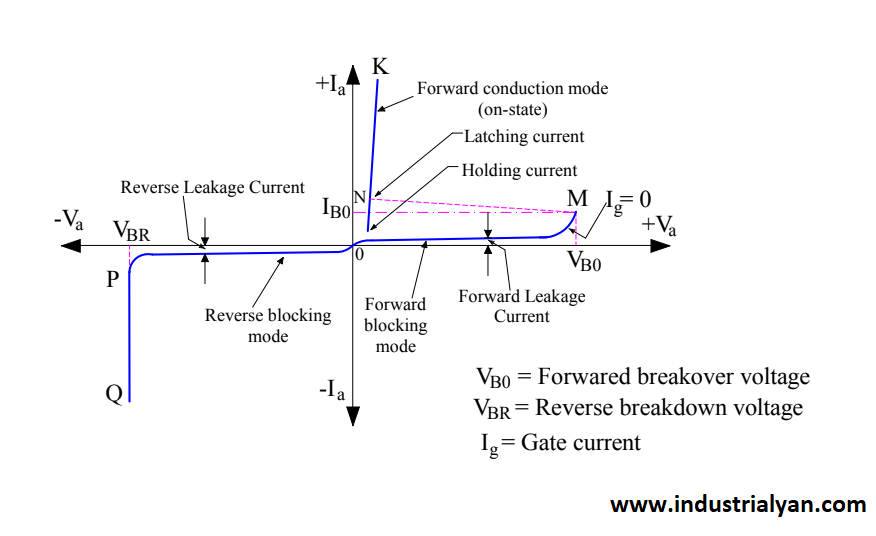

4. Forward Blocking Region

In the forward blocking region, the voltage across the SCR is below its forward breakdown voltage. The SCR behaves as an open circuit, and only a small leakage current flows.

5. Forward Conduction Region

Once the forward voltage across the SCR exceeds the forward breakdown voltage, it enters the forward conduction region. In this region, the SCR starts conducting current, and its voltage drop remains relatively constant.

6. Forward Voltage Drop

The forward voltage drop across an SCR depends on the current passing through it. Typically, the voltage drop is in the range of 1 to 2 volts, but it can vary based on the SCR’s specifications and operating conditions.

7. Holding Current and Latching Current

Holding current is the minimum current required to keep the SCR in the conducting state once it has been triggered. Latching current, on the other hand, is the minimum current necessary to latch the SCR into conduction initially.

8. Reverse Blocking Region

When a reverse voltage is applied across the SCR, it enters the reverse blocking region. In this region, the SCR behaves as an open circuit, and only a small reverse leakage current flows.

9. Gate Triggering

Gate triggering is the process of applying a voltage pulse to the gate terminal to turn on the SCR. It enables precise control of the conduction timing and is crucial for various applications.

10. Gate Triggering Methods

There are several methods to trigger an SCR, including direct triggering, voltage triggering, and current triggering. Each method has its advantages and is suitable for different applications.

11. Turn-off Process

Turning off an SCR involves reducing the anode current below the holding current. This process, known as commutation, requires careful consideration to ensure a smooth transition from the conducting state to the blocking state.

12. Commutation and Snubber Circuits

Commutation circuits are used to assist in turning off SCRs by diverting the current away from the device. Snubber circuits, comprising resistors, capacitors, and diodes, help protect the SCR from voltage spikes and improve its reliability.

13. Protection and Heat Dissipation

SCRs generate heat during operation, and proper heat dissipation is essential to prevent thermal damage.Adequate protection measures, such as implementing overcurrent and overvoltage protection, ensure the safe and reliable operation of the SCR.

14. Applications of SCRs

SCRs find applications in a wide range of fields, including motor control, power supplies, vi characteristics of SCR. lighting control, heating systems, and AC power control. Their ability to handle high power levels and provide efficient switching makes them invaluable in these areas.

15. Conclusion

Understanding the VI characteristics of SCRs is vital for effectively working with these semiconductor devices. By comprehending the behavior of SCRs in different operating regions, engineers and technicians can optimize their use and ensure reliable and efficient performance in various applications.

FAQs

Q1. Can SCRs handle high voltage levels? Yes, SCRs are designed to handle high voltage levels, making them suitable for applications requiring high-power switching.

Q2. What is the forward voltage drop of an SCR? The forward voltage drop of an SCR typically ranges from 1 to 2 volts, depending on the operating conditions and specifications.

Q3. Are there any special considerations for heat dissipation in SCR circuits? Yes, SCR circuits generate heat during operation, and proper heat dissipation techniques, such as using heat sinks, are necessary to prevent thermal damage.

Q4. How can I protect SCRs from voltage spikes? Snubber circuits, vi characteristics of scr,consisting of resistors, capacitors, and diodes, can be used to protect SCRs from voltage spikes and ensure their reliability.

Q5. What are some common applications of SCRs? SCRs are widely used in motor control, power supplies, lighting control, heating systems, and AC power control applications due to their high-power handling capabilities.

In conclusion, understanding the VI characteristics of SCRs is crucial for effectively utilizing these semiconductor devices in various electrical applications. By comprehending their behavior in different operating regions, engineers and technicians can ensure reliable and efficient performance while optimizing their use. SCRs offer precise control, high power handling, and efficient switching, making them an indispensable component in modern electronic systems.

You can follow us on LinkedIn

You can read this Informative article.

I am a highly motivated and skilled individual with a passion for Electrical engineering. I have 1 year of experience in Robotics and Electrical engineering, which has allowed me to develop a strong set of skills in PLC, Painting Robots, SCADA. I am a quick learner and am always looking for new challenges and opportunities to expand my knowledge and skills. I am a team player and enjoy working with others to achieve a common goal. Successfully completed many projects for a various clients in the automobile sector.

Thank You