Hello guys, we use a braking resistor as an electrical component in electrical and electronic circuits to dissipate excess energy in the form of heat. We commonly use it in applications where we need to slow down or stop a motor or other rotating machinery quickly and efficiently.

What is a Braking Resistor? You should Know About it.

People commonly use the braking resistor in applications where they need to slow down or stop a motor or rotating machinery quickly and efficiently. When a motor or other rotating machinery runs, it possesses kinetic energy that it must dissipate when they stop the machine. If they simply switch off the machine, the energy will cause a surge of current that can damage the electrical components of the circuit, including the motor.

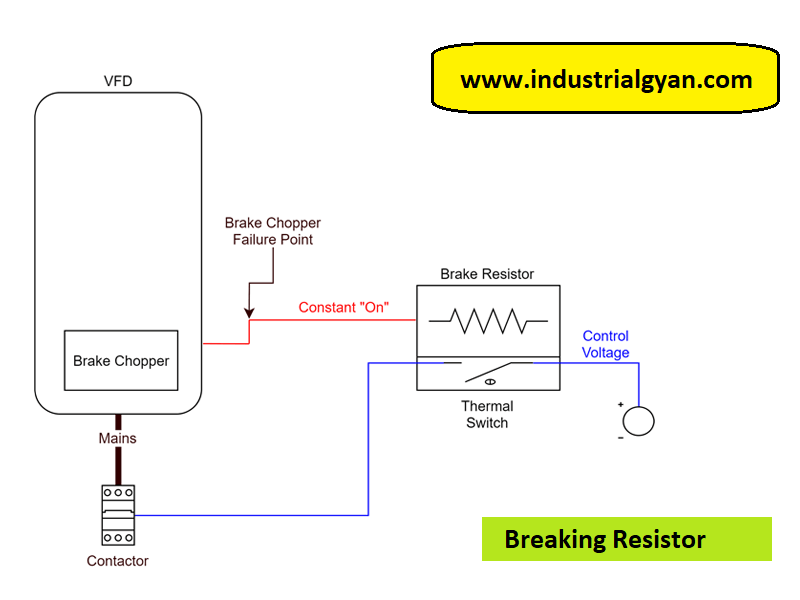

Breaking Resistor (VFD)

To prevent this issue, people connect a braking resistor in parallel with the motor. The breaking resistor provides a path for the energy to dissipate as heat. When they stop the machine, the energy transfers to the resistor, which absorbs and dissipates heat. This process enables the motor to slow down and stop smoothly without causing damage to the circuit.

Breaking resistors are commonly used in applications such as cranes, elevators, and other heavy machinery.

Working of The Braking Resistors

The electrical energy generated by a motor or machine is dissipated as heat by the braking resistor when it is decelerated or stopped. The resistor is connected in parallel with the motor and absorbs the energy, which is converted into heat due to the resistance. The dissipated heat enables smooth deceleration or stopping of the motor.

The protection of the circuit’s electrical components from damage caused by excess energy. This allows precise control over the speed of the machine and is used in applications such as elevators and cranes.

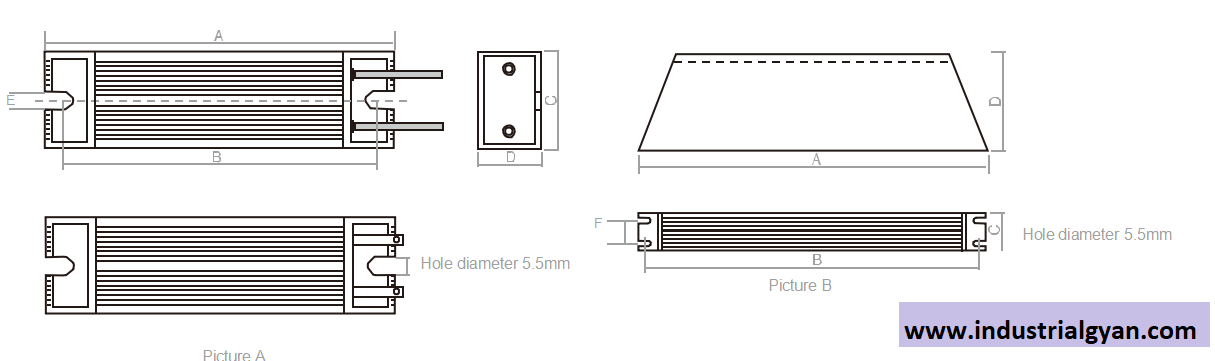

Breaking Resistor

Overall, the braking resistors provide an efficient and effective way to control the deceleration and stopping of a motor or machine, while also protecting the electrical components of the circuit from damage due to excess energy.

Application of the braking resistor

- Electric vehicles and trains also use the braking resistor to slow down or stop when the brakes are applied. In conjunction with regenerative braking systems. The braking resistor provides a way to dissipate excess energy generated by the regenerative braking system.

- The braking resistor is also a crucial component in cranes and hoists, providing precise control over the speed of the load for safe and efficient operation. When the load is lowered or stopped. The braking resistors allows for smooth and controlled deceleration, preventing damage to the load and the crane system.

- The braking resistor is employed in many other industrial and commercial systems such as wind turbines, conveyor systems, and manufacturing equipment. In each of these applications.

- One of the primary applications of the braking resistor is in elevators and lifts. In these systems. The braking resistor ensures a smooth and safe deceleration of the lift car when it reaches its destination.

- The braking resistors is a vital component in various electrical and electronic systems. Providing a way to dissipate excess energy generated by the kinetic energy of a machine or motor.

What is a dynamic braking resistor?

A dynamic braking resistors is a type of resistor used in electrical and electronic systems to quickly dissipate excess electrical energy generated by a motor or machine when it is decelerated or stopped. It works in conjunction with a regenerative braking system to convert the motor’s kinetic energy into electrical energy.

Which is then stored in batteries or capacitors. When the regenerative braking system is unable to store any more energy, the dynamic braking resistors is activated to dissipate. The excess energy generated by the motor prevents damage to the electrical components and extends the system’s lifespan.

Difference between brake chopper and brake resistor

- Brake Chopper:- An electronic device known as a brake chopper converts the excess energy produced by a motor or machine into a DC voltage that people can feed back into the power supply system. When they decelerate or stop a motor. It generates excess energy that it must dissipate to prevent damaging the motor or other components of the system.

A brake chopper provides a more energy-efficient solution compared to traditional brake resistors, which simply dissipate the excess energy as heat. The brake chopper works by using an insulated gate bipolar transistor (IGBT) to rapidly switch the voltage applied to the motor

- Brake Resistor:-People use a braking resistor as an electrical component in electrical and electronic circuits to dissipate excess energy in the form of heat. They commonly use it in applications where they need to slow down or stop a motor or other rotating machinery quickly and efficiently.

The breaking resistor provides a path for the energy to be dissipated as heat. When the machine is stopped. The energy is transferred to the resistor, which absorbs it and dissipates it as heat.

Frequently Asked Questions (FAQ)

- What is a dynamic braking resistor, and how does it work?

A dynamic braking resistor is a type of braking resistor used to dissipate the excess energy generated by a motor or machine during deceleration or braking. It works by converting the excess energy into heat. Which is then dissipated by the resistor. This process helps to prevent damage to the motor or other components of the system.

- What is a braking resistor, and what is its purpose?

A braking resistor is a passive device used to dissipate the excess energy generated by a motor or machine during deceleration or braking. It works by converting the excess energy into heat. Which is then dissipated by the resistor. This process helps to prevent damage to the motor or other components of the system.

Frequently Asked Questions (FAQ) (Brake Chopper)

- What is a brake chopper, and how does it differ from a braking resistor?

A brake chopper is an electronic device used to convert the excess energy generated by a motor or machine into a DC voltage that can be fed back into the power supply system. It works by using an insulated gate bipolar transistor (IGBT) to rapidly switch the voltage applied to the motor. Effectively creating a DC voltage that can be fed back into the power supply. This process allows for the energy to be reused instead of dissipated as heat, resulting in a more energy-efficient operation. In contrast, a braking resistor simply dissipates the excess energy as heat.

- When should I use a dynamic braking resistors versus a brake chopper?

A dynamic braking resistor is typically used in low-power applications where energy efficiency is not a primary concern. It is a passive device that dissipates excess energy as heat, making it less energy-efficient than a brake chopper. Brake choppers are more commonly used in high-power applications where energy efficiency is important. As they allow for the energy generated during braking to be reused instead of being dissipated as heat.

- Can a brake chopper be used without a braking resistors?

While a brake chopper can be used without a braking resistor in some cases. It is not recommended. Without a braking resistor. the voltage generated by the motor during braking can rise to dangerous levels. Potentially causing damage to the motor or other components of the system. A braking resistors helps to limit the voltage rise and protect the system from damage.

For more learn visit air blast circuit breaker

You can also follow us on LinkedIn

I am a highly motivated and skilled individual with a passion for Electrical engineering. I have 1 year of experience in Robotics and Electrical engineering, which has allowed me to develop a strong set of skills in PLC, Painting Robots, SCADA. I am a quick learner and am always looking for new challenges and opportunities to expand my knowledge and skills. I am a team player and enjoy working with others to achieve a common goal. Successfully completed many projects for a various clients in the automobile sector.

Thank You