Introduction

Are you looking for an efficient and versatile solution for fluid transfer? Look no further than the internal gear pump. This remarkable piece of machinery has revolutionized how various industries transfer fluids. In this comprehensive guide, we will explore the inner workings, benefits, applications, and maintenance tips for the internal gear pump. So, let’s dive right in and uncover the secrets behind this ingenious invention.

Internal Gear Pump: A Closer Look

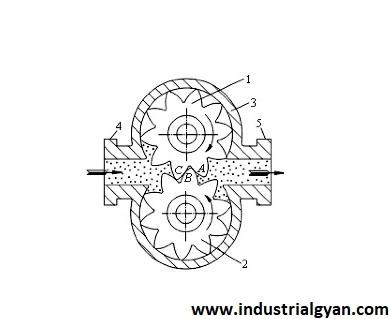

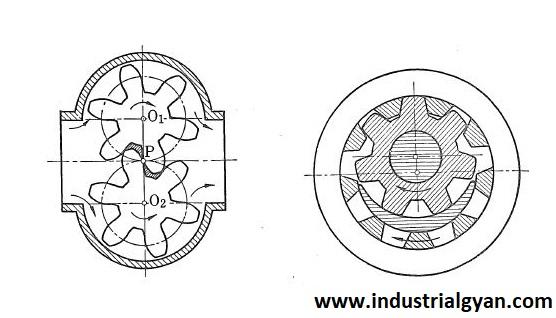

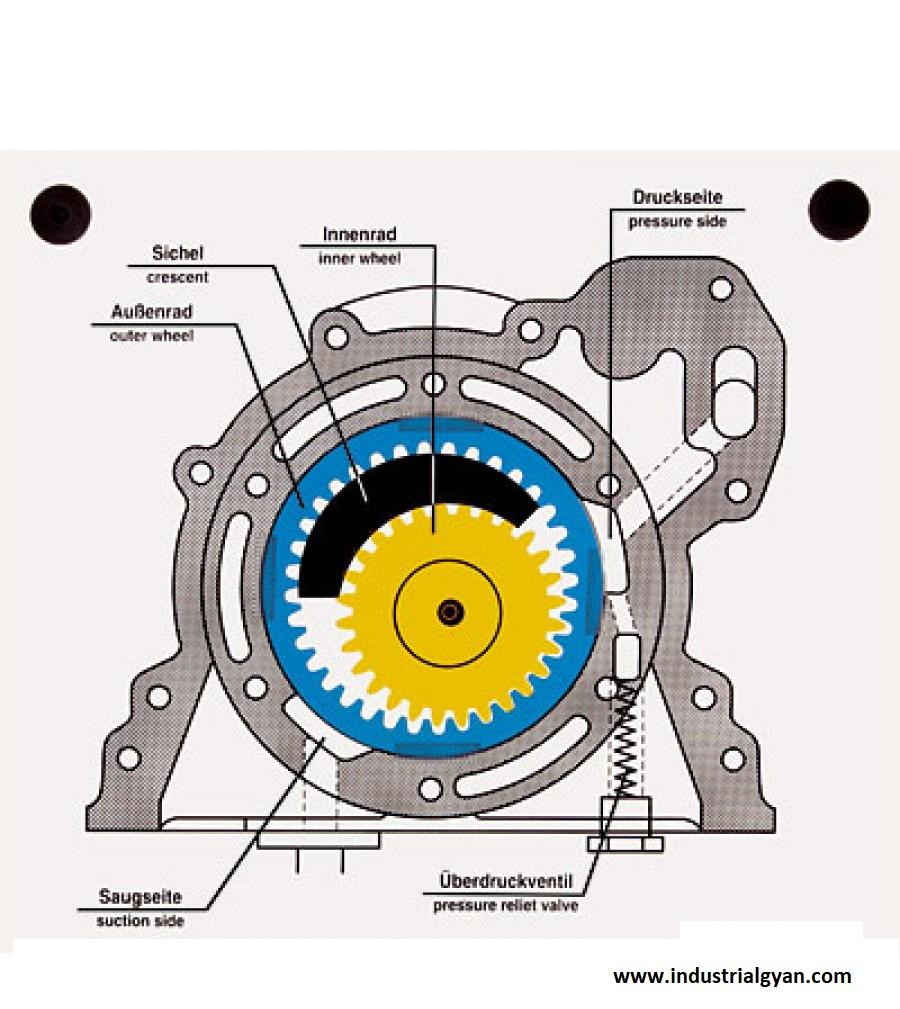

An internal gear pump, also known as a gear-within-a-gear pump, is a positive displacement pump that uses the meshing of gears to transfer fluid. It consists of an outer rotor, an inner rotor, and a crescent-shaped partition that forms the pumping chambers. The gears rotate, causing fluid to enter the suction port and become trapped between the gear teeth, thus creating a sealed chamber. As the gears continue to rotate, they carry the fluid to the discharge port, resulting in a continuous flow.

How Does an Internal Gear Pump Work?

- Gear Engagement: As the pump starts, the outer and inner gears engage, forming a tight seal.

- Suction Stroke: During the suction stroke, the gears separate, creating a vacuum that draws fluid into the pump through the suction port.

- Fluid Trapping: As the gears rotate, the fluid becomes trapped in the gear teeth cavities due to the tight tolerances between the gears and the casing.

- Fluid Discharge: The fluid is carried to the discharge port as the gears continue to rotate. Resulting in a continuous flow of fluid.

- Return Stroke: The gears re-engage, compressing the fluid and preparing for the next suction stroke.

Advantages of Internal Gear Pumps

Internal gear pumps offer several advantages over other types of pumps, making them a popular choice in various industries. Let’s explore some of their key benefits:

- Versatility: Internal gear pumps are highly versatile and can handle a wide range of fluids, including viscous liquids, corrosive substances, and abrasive materials.

- Efficiency: Due to their positive displacement nature, internal gear pumps provide consistent and precise fluid transfer, making them highly efficient in various applications.

- Self-Priming: Internal gear pumps are capable of self-priming. Meaning they can evacuate air from the suction line and start pumping without the need for manual priming.

- Reversible Operation: These pumps can operate in both directions. Allowing for easy reversal of flow or changing the direction of rotation without any modifications.

- Compact Design: Internal gear pumps are known for their compact and space-saving design, making them suitable for installations with limited space.

- Low Noise and Vibration: The precise meshing of gears in internal gear pumps results in smooth and quiet operation, minimizing noise and vibration levels.

Applications of Internal Gear Pumps

Internal gear pumps find applications in a wide range of industries where a reliable fluid transfer is essential. Some common applications include:

- Chemical Industry: Internal gear pumps transfer chemicals, acids, solvents, and other corrosive fluids with high accuracy and efficiency.

- Oil and Gas: These pumps play a crucial role in the extraction, refining, and transportation of petroleum products, such as crude oil, gasoline, and lubricants.

- Food and Beverage: The food and beverage industry widely uses internal gear pumps to handle ingredients, syrups, sauces, and other viscous fluids.

- Paint and Coatings: The precise flow control provided by internal gear pumps makes them ideal for transferring paints, coatings, and adhesives in various manufacturing processes.

- Pharmaceuticals: Internal gear pumps ensure the precise and sterile transfer of pharmaceutical liquids, including vaccines, syrups, and medicinal formulations.

- Automotive: These pumps are employed in automotive applications. Such as fuel injection systems, lubrication systems, and hydraulic systems.

Maintenance Tips for Internal Gear Pumps

To ensure optimal performance and longevity of your internal gear pump, follow these maintenance tips:

- Regular Inspections: Periodically inspect the pump for any signs of leaks, wear, or damage. switched reluctance motor Address any issues promptly to avoid costly repairs.

- Proper Lubrication: Ensure the pump is properly lubricated as per the manufacturer’s recommendations. This helps reduce friction and extend the life of the pump.

- Clean Fluids: Use clean and filtered fluids to prevent contaminants from entering the pump and causing damage to the gears and other components.

- Temperature Control: Maintain the operating temperature within the recommended range to prevent excessive heat or cold, which can affect the pump’s performance.

- Seal Maintenance: Check and replace worn-out seals to prevent fluid leakage and maintain the pump’s efficiency.

- Professional Servicing: Periodically engage a professional technician to perform a thorough inspection and servicing of the pump to ensure its optimal performance.

FAQs about Internal Gear Pumps

1. Are internal gear pumps suitable for high-viscosity fluids?

Yes, internal gear pumps are highly suitable for handling high-viscosity fluids. Their positive displacement design ensures consistent flow and efficient transfer of such fluids.

2. Can internal gear pumps handle abrasive materials?

Internal gear pumps are capable of handling abrasive materials. stator and rotor But it’s important to choose materials of construction that can withstand the abrasive nature of the fluid being pumped.

3. How do internal gear pumps compare to centrifugal pumps?

Internal gear pumps and centrifugal pumps serve different purposes. While centrifugal pumps are ideal for high-flow, low-pressure applications, internal gear pumps excel in precise flow control and handling viscous fluids.

4. Can an internal gear pump run dry?

Running an internal gear pump dry is not recommended due to the potential for excessive wear and damage to the gears and other components. It is important to ensure proper priming and fluid supply.

5. Are internal gear pumps self-priming?

Yes, internal gear pumps are self-priming, which means they can evacuate air from the suction line and start pumping without the need for manual priming.

6. What maintenance is required for internal gear pumps?

Regular inspections, proper lubrication, clean fluids, seal maintenance, and professional servicing are essential for the maintenance of internal gear pumps. Following manufacturer guidelines is crucial.

Conclusion

The internal gear pump is a remarkable invention that has revolutionized fluid transfer in various industries. Its efficient and versatile nature, combined with its compact design and precise flow control. Make it an ideal choice for a wide range of applications. By understanding how internal gear pumps work and following proper maintenance practices, you can ensure their optimal performance and longevity. So, whether you need to transfer viscous fluids, corrosive chemicals, or abrasive materials, the internal gear pump is the go-to solution for all your fluid transfer needs.

You can follow us on LinkedIn

I am a highly motivated and skilled individual with a passion for Electrical engineering. I have 1 year of experience in Robotics and Electrical engineering, which has allowed me to develop a strong set of skills in PLC, Painting Robots, SCADA. I am a quick learner and am always looking for new challenges and opportunities to expand my knowledge and skills. I am a team player and enjoy working with others to achieve a common goal. Successfully completed many projects for a various clients in the automobile sector.

Thank You