Lightning is a natural phenomenon that can be both beautiful and dangerous. While it may look mesmerizing, it poses a significant threat to buildings and equipment. Lightning can strike any structure that is not properly protected, causing damage or even destroying it entirely. To prevent this, lightning arresters are used. In this article, we will take a closer look at the different types of lightning arresters and how they work. In have included the lightning arrester types.

Table of Contents

- Introduction

- What is a Lightning Arrester?

- Types of Lightning Arresters

- Rod or Rod-gap Arresters

- Horn-gapped Arresters

- Multi-Gap Arresters

- Expulsion Type Lightning Arresters

- Valve Type Lightning Arresters

- How Lightning Arresters Work

- Factors to Consider When Selecting a Lightning Arrester

- Voltage Rating

- Surge Current Rating

- MCOV Rating

- Follow Current Rating

- Installation and Maintenance of Lightning Arresters

- Advantages of Lightning Arresters

- Disadvantages of Lightning Arresters

- Conclusion

- FAQs

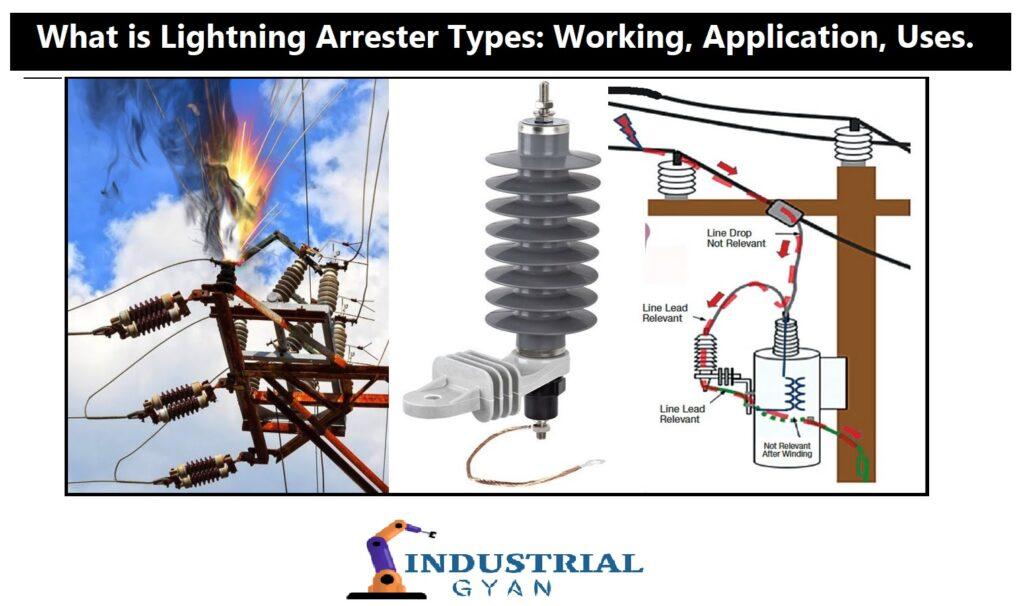

What is a Lightning Arrester?

A lightning arrester protects electrical equipment from lightning strikes’ harmful effects. This device diverts lightning strikes to the ground, safeguarding the equipment and building against damage. You install the lightning arrester between the equipment and the ground, and it operates by creating a low-resistance path to the ground for the lightning current. With included the lightning arrester types.

Types of Lightning Arresters

There are several types of lightning arresters available on the market. Each type has its unique features and applications. Let’s take a closer look at the most common types of lightning arresters.With included the lightning arrester types.

1. Rod or Rod-gap Arresters

Rod or Rod-gap Arresters are the simplest type of lightning arresters. A lightning arrester comprises a metal rod or wire linked to the ground. The wire conducts the lightning to the ground when it strikes the rod. Residential buildings and other low-voltage applications frequently use these types of arresters.

2. Horn-gapped Arresters

Horn-gapped Arresters are more complex than rod or rod-gap arresters. They consist of a series of metal horns that are arranged in a line. When lightning strikes the horns, the current is conducted to the ground through a series of gaps between the horns. Horn-gapped Arresters are commonly used in high-voltage applications.

3. Multi-Gap Arresters

Multi-Gap Arresters are similar to horn-gapped arresters but have multiple gaps in parallel. The gaps provide multiple paths for the current to flow to the ground, reducing the risk of arcing and damage to the arrester.

4. Expulsion Type Lightning Arresters

Expulsion Type Lightning Arresters work by expelling the lightning current to the ground through a spark gap. When lightning strikes the arrester, the spark gap ionizes, allowing the current to flow through it and to the ground.

5. Valve Type Lightning Arresters

Valve Type Lightning Arresters are similar to expulsion-type lightning arresters but have a valve mechanism that controls the flow of current. When the voltage exceeds a certain level, the valve opens, allowing the current to flow to the ground.

How Lightning Arresters Work

When lightning strikes an unprotected structure or equipment, it creates a surge of electricity that can cause significant damage. Lightning arresters work by providing a low-resistance path to the ground, diverting the surge of electricity away from the equipment. With included the lightning arrester types.

The lightning arrester is connected in parallel with the equipment it is protecting. When a lightning surge occurs, the arrester becomes conductive, diverting the surge to the ground. type of micrometer Once the surge is over, the arrester returns to its normal state, ready to protect the equipment from the next surge.

Factors to Consider When Selecting a Lightning Arrester

When selecting a lightning arrester, there are several factors that need to be considered to ensure that it is suitable for the application.

1. Voltage Rating

The voltage rating of the arrester must be higher than the maximum voltage that the equipment can handle. If the arrester’s voltage rating is too low, it may fail to protect the equipment.

2. Surge Current Rating

The surge current rating of the arrester must be higher than the maximum current that the equipment can handle. If the arrester’s surge current rating is too low, it may fail to protect the equipment.

3. MCOV Rating

The MCOV (Maximum Continuous Operating Voltage) rating of the arrester must be lower than the maximum voltage that the equipment can handle. If the arrester’s MCOV rating is too high, it may cause damage to the equipment.

4. Follow Current Rating

The follow current rating of the arrester must be high enough to allow the equipment to operate normally. If the follow current rating is too low, it may cause damage to the equipment. electron beam machining diagram

Installation and Maintenance of Lightning Arresters

To ensure adequate protection, it’s essential to install lightning arresters correctly. Installing them as close to the protected equipment as possible, with a low-resistance path to ground, is crucial. Regular inspections are necessary to confirm proper functioning of the arrester. If you find any damage during inspection, you must replace the arrester immediately.

Advantages of Lightning Arresters

There are several advantages to using lightning arresters, including:

- Protects equipment from lightning strikes

- Reduces the risk of downtime due to equipment failure

- Increases the lifespan of equipment

- Improves safety for personnel

Disadvantages of Lightning Arresters

There are also some disadvantages to using lightning arresters, including:

- They can be expensive to install

- They require regular maintenance to ensure they are functioning correctly

- They can be damaged by lightning strikes, requiring replacement

Conclusion

Lightning arresters are an essential part of any building’s electrical system. They protect equipment from lightning strikes, reducing downtime and improving safety. There are several types of lightning arresters available, each with its unique features and applications. When selecting a lightning arrester, it is essential to consider several factors, including voltage rating, surge current rating, MCOV rating, and follow current rating.

FAQs

- What is the purpose of a lightning arrester?

A lightning arrester is used to protect electrical equipment from the harmful effects of lightning strikes.

- What types of lightning arresters are available?

There are several types of lightning arresters available, including rod or rod-gap arresters, horn-gapped arresters, multi-gap arresters, expulsion-type lightning arresters, and valve-type lightning arresters.

- How do lightning arresters work?

Lightning arresters work by providing a low-resistance path to the ground, diverting the surge of electricity away from the equipment.

- What factors should be considered when selecting a lightning arrester?

When selecting a lightning arrester, it is essential to consider several factors, including voltage rating, surge current rating, MCOV rating, and follow current rating.

- What are the advantages of lightning arresters?

The advantages of lightning arresters include protection of equipment from lightning strikes, reduction of downtime due to equipment failure, increase of equipment lifespan, and improvement of safety for personnel.

- What are the disadvantages of lightning arresters?

The disadvantages of lightning arresters include their cost to install, the requirement for regular maintenance to ensure proper function, and susceptibility to damage from lightning strikes, which can require replacement.

You Can Follow us on LinkedIn

I am a highly motivated and skilled individual with a passion for Electrical engineering. I have 1 year of experience in Robotics and Electrical engineering, which has allowed me to develop a strong set of skills in PLC, Painting Robots, SCADA. I am a quick learner and am always looking for new challenges and opportunities to expand my knowledge and skills. I am a team player and enjoy working with others to achieve a common goal. Successfully completed many projects for a various clients in the automobile sector.

Thank You