Hello guys, Today we are discussing the topic of the LVDT (Linear variable differential transformer) including the various topic related to this such as the Advantages of LVDT, Application of LVDT, Working & Construction of the LVDT and etc. A single insulator unit mounted on a metal pin and directly attached to the supporting structure provides insulation and support to the power transmission equipment in low-voltage power transmission and distribution systems.

What is LVDT? (Linear Variable Differential Transformer)

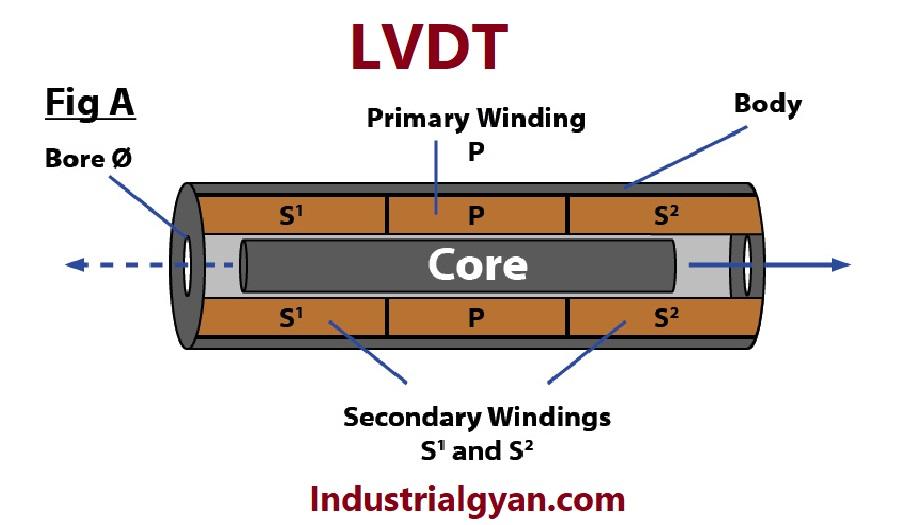

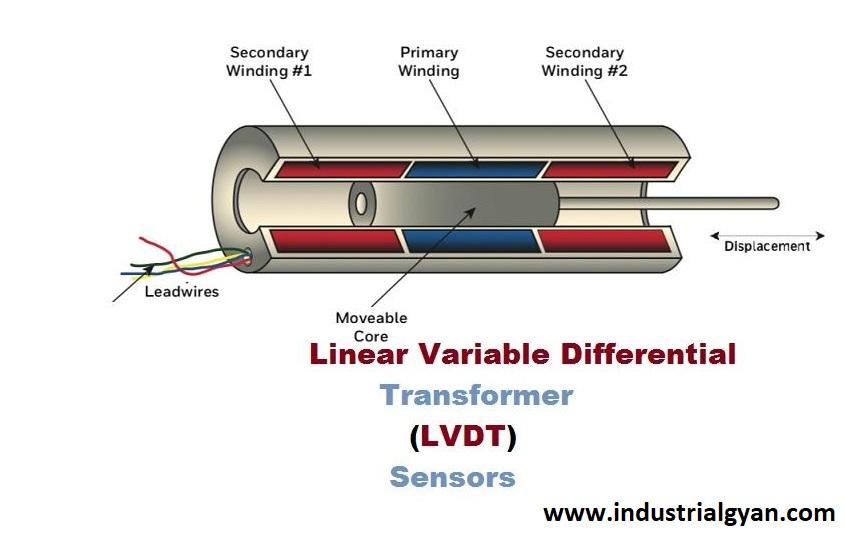

The LVDT is an electromechanical sensor that measures linear displacement or position. It comprises a primary coil and two secondary coils wound on a cylindrical ferromagnetic core. Applying an AC voltage to the primary coil generates a magnetic field that induces voltages in the secondary coils.

The voltage induced in each secondary coil is proportional to the position of the core along the axis of the LVDT. By measuring the difference between the voltages induced in the two secondary coils, the LVDT provides a highly accurate measurement of the linear displacement of the core.

LVDTs are famous for their high accuracy, reliability, and long-term stability because they lack any moving parts that can wear out over time.

Working of the LVDT

The work of the LVDT can describe below:-

Applying an AC voltage to the primary coil of the LVDT generates a magnetic field that passes through its ferromagnetic core. The core has two secondary coils wound around it in opposite directions, and the magnetic field induces a voltage in each of them.

The voltage induced in each secondary coil is proportional to the amount of magnetic flux that passes through it. The amount of magnetic flux passing through the coil depends on the position of the core along the axis of the LVDT. When the core is centered between the two secondary coils. The magnetic flux passing through each coil is equal, and the voltages induced in the two coils cancel out. As the core moves away from the center position,

By measuring the difference between the voltages induced in the two secondary coils, the LVDT can accurately determine the linear displacement of the core along its axis. The output of the LVDT is typically an AC voltage signal. Which can be amplified, filtered, and converted into a digital signal for further processing and analysis.

Construction of the LVDT

A cylindrical rod made of ferromagnetic material, such as nickel-iron alloy or soft iron, constitutes the ferromagnetic core of the LVDT. It is the moving part of the LVDT, and its position along the axis of the LVDT determines the output voltage. Primary coil The primary coil is a cylindrical winding of wire that is located at the center of the LVDT. When an AC voltage is applied to the primary coil. It generates a magnetic field that passes through the core and induces voltages in the secondary coils.

The two secondary coils have identical size and shape, and they position on either side of the primary coil, connected by a series of opposition. The housing serves as a protective casing, which surrounds the primary and secondary coils, and the core. It is typically made of non-magnetic materials such as stainless steel or plastic.

Application of LVDT

The LVDT has various applications across the various application:-

- Aerospace:-Aircraft use LVDTs to measure the position, displacement, and vibration of components like flaps, landing gear, and engine controls.

- Automotive:- Automobiles use LVDTs to measure suspension travel, ride height, and steering angle.

- Manufacturing:-In manufacturing, LVDTs measure the position of machine tools, parts, and robotic arms, while in medical equipment.

- Medical:- They measure the position and movement of devices like catheters and probes.

- Power generation:-Power plants use LVDTs to measure the position of control valves, steam turbines, and fuel injectors.

- Civil engineering:- In civil engineering, LVDTs measure the displacement and settlement of structures like bridges, dams, and buildings.

Type of the LVDT

There are many types of LVDT mentioned below:-

- DC-operated LVDTs

- High-temperature LVDTs

- Submersible LVDTs

- Miniature LVDTs

- Digital LVDTs

- Radiation-resistant LVDTs

Advantages of the LVDT

- High accuracy:- LVDTs can provide high-accuracy measurements with a resolution of up to 0.01% of full scale.

- Wide linear range:- LVDTs have a wide linear range of measurement. Typically from fractions of a millimeter up to several centimeters or more.

- Good repeatability:- LVDTs offer good repeatability, meaning that they can provide consistent and reliable measurements over time.

- Easy to use:- LVDTs are easy to install and use, and they can be integrated with other measurement and control systems.

for more information auto transformer starter

FAQ (Frequently Asked Question)

1)What does LVDT stand for?

LVDT stands for Linear Variable Differential Transformer.

2) How does an LVDT work?

An LVDT functions by attaching a movable core to the object being measured, which moves inside a tube containing three coils: a primary coil and two secondary coils. Once the primary coil is excited with an AC voltage, it induces voltages in the secondary coils that are proportional to the position of the core.

3)What is the range of an LVDT?

The range of an LVDT varies depending on the specific model and application. But it can typically measure displacements and positions from fractions of a millimeter up to several centimeters or more.

4)What is the accuracy of an LVDT?

The accuracy of an LVDT can be as high as 0.01% of full scale, depending on the specific model and application.

5)Can LVDTs be used in harsh environments?

The LVDT can operate in harsh environments, such as high temperatures, corrosive substances, and radiation, as designers can create them accordingly.

6)What are some common applications of LVDTs?

LVDTs find common usage in aerospace, automotive, manufacturing, medical, power generation, and civil engineering applications.

7)Can LVDTs perform dynamic measurements?

Yes, LVDTs can provide high-resolution measurements that allow them to detect small changes in displacement or position, making them suitable for measuring dynamic movements.

I am a highly motivated and skilled individual with a passion for Electrical engineering. I have 1 year of experience in Robotics and Electrical engineering, which has allowed me to develop a strong set of skills in PLC, Painting Robots, SCADA. I am a quick learner and am always looking for new challenges and opportunities to expand my knowledge and skills. I am a team player and enjoy working with others to achieve a common goal. Successfully completed many projects for a various clients in the automobile sector.

Thank You