Today, we are discussing the solenoid, including its working principle, diagram, types, applications, pros, and cons.

What is Solenoid?

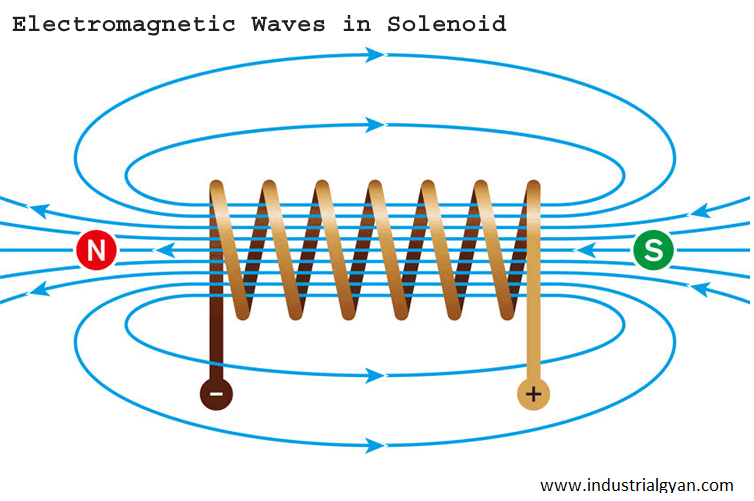

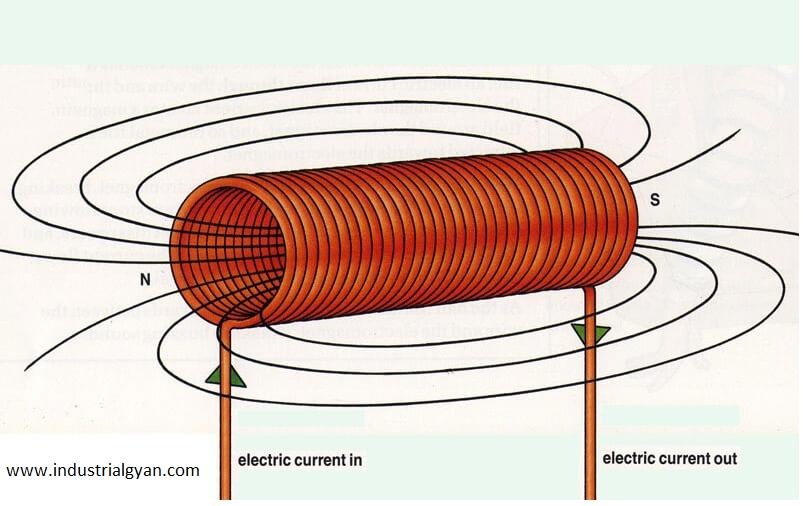

A long wire form wrapped in a turn formed into a coil connected to a Direct current (DC) supply. When the coil connected to the supply produced magnetic flux from the coil.

- The solenoid is an electric component that converts electrical energy into mechanical energy by using electric flux to produce linear motion.

- Mainly use it as an inductor, a moving electromagnetic, and a wireless antenna receiver.

- It works solely by using the principle of electromagnetism and behaves like a magnetic bar.

Solenoid Diagram

Working Principle:-

The Solenoid converts electrical energy into mechanical energy by using the principle of Electromagnetic induction. Specifically, a long coil-shaped wire, connected to a DC supply via a battery, produces electric flux inside the coil and exerts a force of linear motion. Additionally, according to the principle of electromagnetic, it behaves like a magnetic bar.

Solenoid Coil

Method of increasing the capacity of the coil:-

The capacity of a solenoid can be increased through various methods such as:

- By increasing the current in the electrical circuit.

- By increasing the number of turns in the coil and forming a dense coil. This method is highly effective in increasing the capacity of the solenoid.

Types of the Solenoid:-

- AC laminated Solenoid.

- Linear Solenoid.

- Rotatory Solenoid.

- DC-D frame Solenoid.

- DC-C frame Solenoid.

AC laminated Solenoid:-

Use the AC laminated solenoid primarily for multiple strokes as it is more efficient than DC solenoids. The steel core laminate reduces stray losses, known for high force in the first strokes and silent operation producing very low sound during operation.

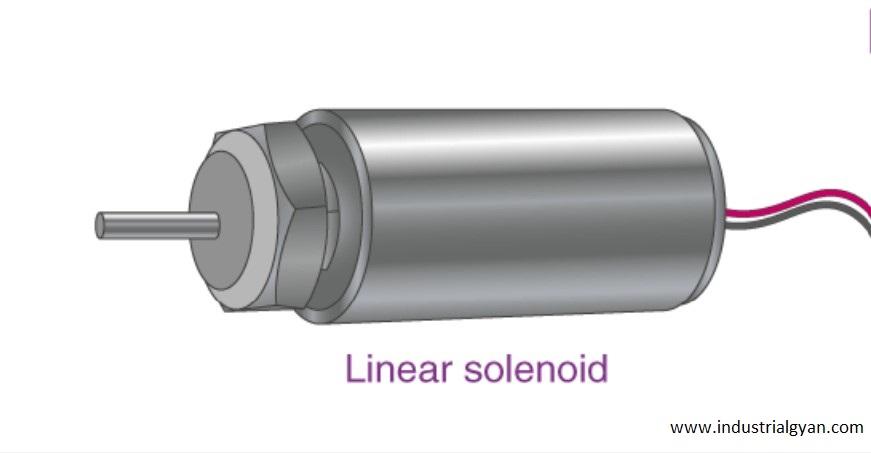

Linear Solenoid:-

A linear solenoid is mostly used for a push-pull type of applications. In particular, it has a wrap-around circular coil on the core and operates by flowing current inside the circuit. It is primarily utilized in starting types of applications.

Rotatory Solenoid:-

Industrial operations widely use this type of rotatory solenoid to automate the process. It also has a core and coil like other solenoids.

DC-C frame solenoid:-

Design this type of DC-C as a C-shaped core solenoid. Rarely use this DC-D frame solenoid.

DC – D frame solenoid:-

Divide the core into a two-piece frame covering the overall coil. This operates in only stroke force operation and also operates in AC supply. Thedyknown as a DC-D frame solenoid.

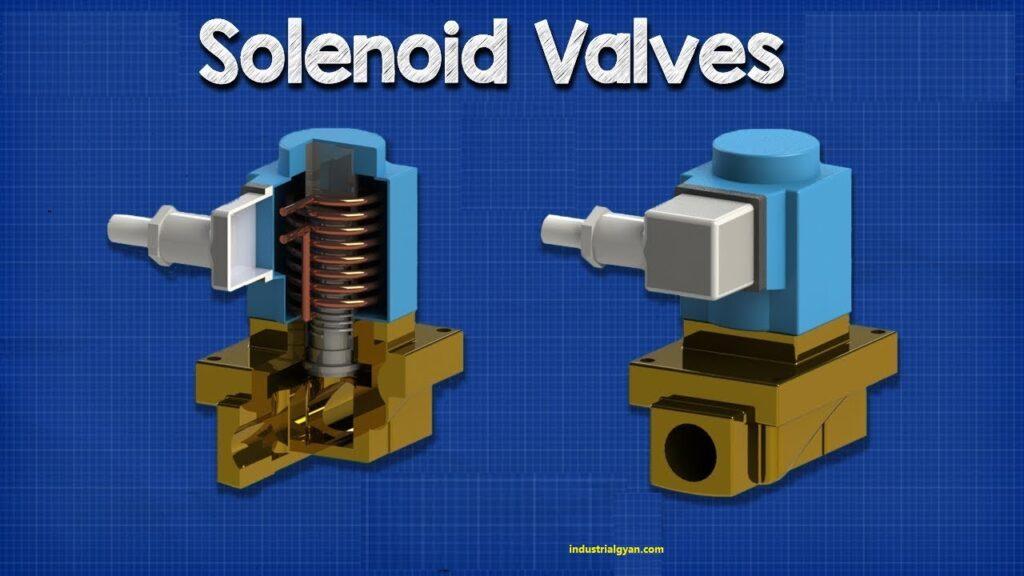

Applications:-

- “Widely use solenoid valves to control the flow of gases, fluids, etc.

- Automation commonly uses them and they can be found in various applications such as machines, printers, gaming equipment, and engineering machinery.

- For more information on solenoid valves, you can visit a relevant website here.

Top Solenoid manufacturers:-

I am a highly motivated and skilled individual with a passion for Electrical engineering. I have 1 year of experience in Robotics and Electrical engineering, which has allowed me to develop a strong set of skills in PLC, Painting Robots, SCADA. I am a quick learner and am always looking for new challenges and opportunities to expand my knowledge and skills. I am a team player and enjoy working with others to achieve a common goal. Successfully completed many projects for a various clients in the automobile sector.

Thank You

Hi there! I don’t know if I could thank you enough for showing us how fantastic solenoid valves are in regulating fluid flow. There’s a hydraulic machine in my local workshop that needs to be fixed using some spare parts. I believe this article would help the owner find the right material from a supplier soon enough.