Introduction

In today’s fast-paced world, technology plays a crucial role in enhancing our daily lives. One such technological marvel is the vibration motor. Whether it’s in our smartphones, gaming consoles, fitness trackers, or even household appliances, vibration motors are everywhere. In this comprehensive guide, we will delve deep into the world of vibration motors, exploring their functionality, applications, and benefits. So, fasten your seatbelts and get ready for an exciting ride!

What is a Vibration Motor?

A vibration motor is a compact and robust device that converts electrical energy into mechanical vibrations. acsr conductor These motors generate controlled vibrations or oscillations, which are used for a wide range of purposes, such as alerting users, creating haptic feedback, and providing tactile sensations. The compact size and versatility of vibration motors have made them an integral part of various electronic devices.

How Does a Vibration Motor Work?

Vibration motors operate based on the principle of electromagnetic induction. Inside a vibration motor, there is an eccentric weight or a rotating mass that is off-center. When an electrical current flows through the motor’s coils, it creates a magnetic field. This magnetic field interacts with the rotating mass, causing it to move in a circular motion. This motion, in turn, generates vibrations or oscillations.

Types of Vibration Motors

There are several types of vibration motors available in the market, each designed for specific applications. Let’s take a closer look at some of the commonly used types:

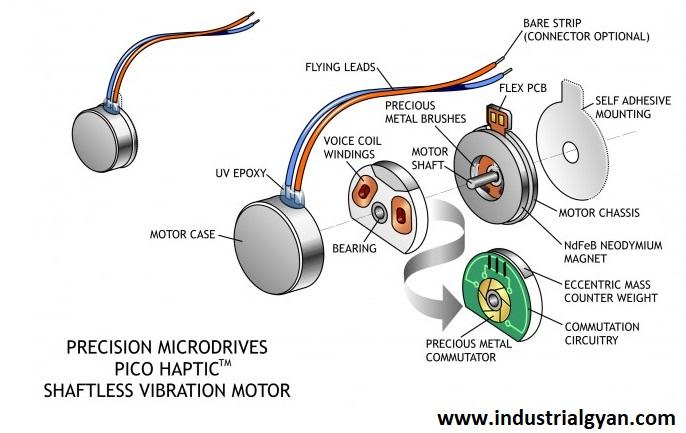

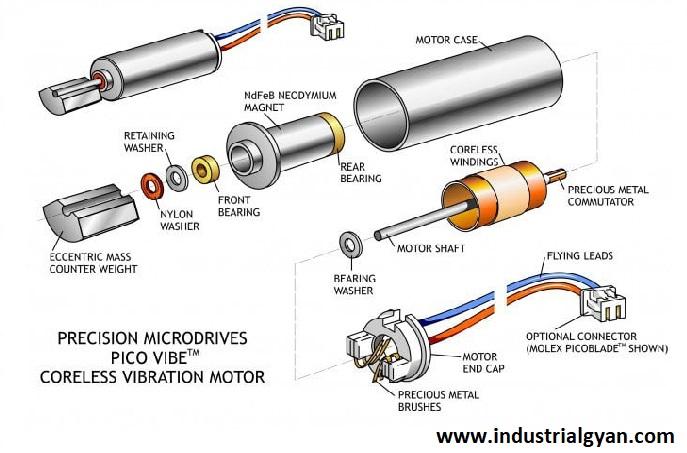

1. Eccentric Rotating Mass (ERM) Motors

ERM motors, also known as pager motors, are the most common type of vibration motors. They consist of an eccentric mass attached to a motor shaft. When the motor rotates, the off-center mass generates vibrations. ERM motors are widely used in devices like mobile phones, pagers, and game controllers.

2. Linear Resonant Actuators (LRAs)

LRAs are precision motors that produce linear vibrations instead of rotational vibrations. moving iron instrument They utilize a voice coil mechanism to generate vibrations. LRAs are popular in applications where precise control over vibration intensity and frequency is required. They find applications in devices like wearable fitness trackers and haptic feedback systems.

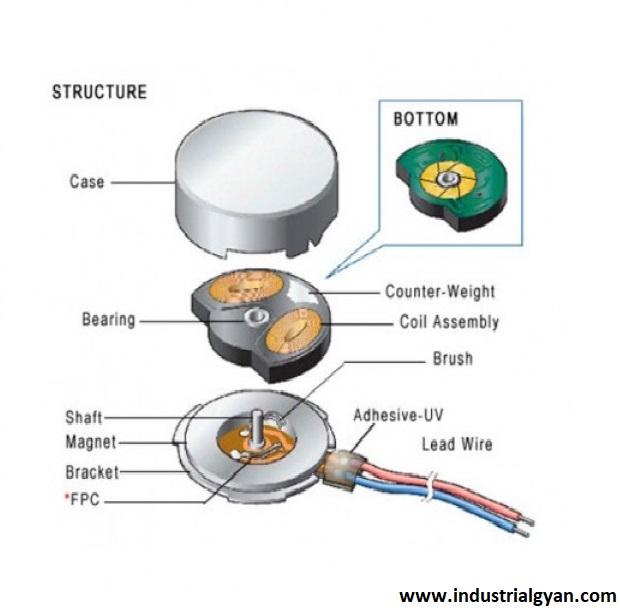

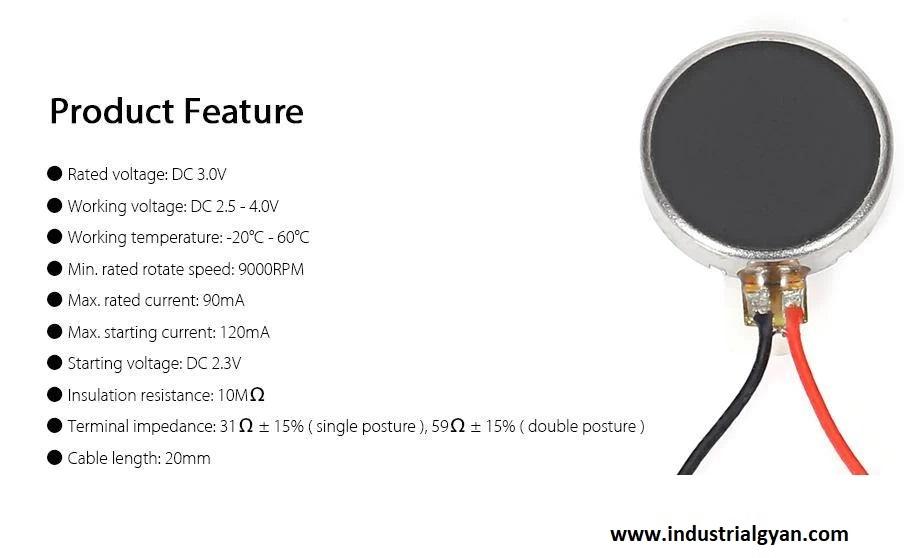

3. Coin Motors

Coin motors, also known as pancake motors, are thin and flat-vibration motors that resemble a coin. They consist of a rotating weight coupled with a small DC motor. Coin motors are commonly used in devices where space is a constraint, such as smartwatches and medical devices.

4. Brushless Coin Motors

Brushless coin motors are an advanced version of coin motors. They eliminate the need for brushes, resulting in reduced friction and enhanced durability. These motors find applications in devices that require long-lasting and reliable vibration, such as virtual reality (VR) controllers and handheld gaming devices.

Applications of Vibration Motors

Vibration motors have an extensive range of applications across various industries. Let’s explore some of the key applications:

1. Mobile Devices and Wearables

Vibration motors are extensively used in mobile phones and wearables to provide haptic feedback. They create vibrations that alert users about incoming calls, messages, or notifications. Additionally, in fitness trackers, vibration motors produce vibrations to convey activity progress or alerts.

2. Gaming and Virtual Reality

In the gaming industry, vibration motors play a vital role in enhancing the gaming experience. They provide tactile feedback, making games more immersive and realistic. Vibration motors are often integrated into gaming controllers, joysticks, and steering wheels, adding an extra layer of excitement to the gameplay. Moreover, in virtual reality systems, vibration motors simulate realistic sensations, further immersing users in virtual worlds.

3. Medical Devices

Vibration motors find significant applications in the medical field. They are used in devices like medical alert systems and wearable health monitors to provide tactile alerts for patients. Vibration motors can also be found in medical equipment such as handheld diagnostic devices, where they assist in providing feedback and guidance to healthcare professionals.

4. Automotive Industry

In the automotive industry, various applications employ vibration motors. Vehicle safety systems utilize them to alert drivers through vibrations, such as in lane departure warning systems or collision avoidance systems. Vibration motors are also present in automotive infotainment systems, providing haptic feedback for touchscreens and buttons.

5. Industrial Applications

Vibration motors find numerous applications in industrial settings. Machinery and equipment utilize them to indicate faults, alert operators, or provide status updates. Additionally, vibration motors can be integrated into conveyor systems to assist in material flow and sorting processes. Moreover, they are employed in vibration testing and calibration equipment.

6. Consumer Electronics

From smart home devices to home appliances, vibration motors contribute to enhancing the user experience. Devices like electric toothbrushes utilize them to provide haptic feedback and notify users when it’s time to change brushing areas. Vibration motors are also present in gaming consoles, delivering a tactile response to players during gameplay.

These are just a few examples of the diverse applications of vibration motors. Their versatility and ability to provide tactile feedback make them indispensable in various industries.

Benefits of Vibration Motors

Vibration motors offer several benefits that make them ideal for a wide range of applications. Let’s explore some of the key advantages:

1. Tactile Feedback

One of the primary benefits of vibration motors is their ability to provide tactile feedback. Whether it’s a gentle vibration to indicate a notification or a stronger vibration for alerts, tactile feedback enhances the user experience by providing an additional sensory dimension.

2. Compact Size

Vibration motors are compact and lightweight, making them ideal for integration into small electronic devices. Their small size allows for flexible placement within devices without compromising on functionality.

3. Low Power Consumption

Vibration motors are designed to operate efficiently with minimal power consumption. This is especially important in battery-powered devices like smartphones and wearables, where optimizing power usage is crucial for prolonged battery life.

4. Reliable and Durable

Vibration motors are built to withstand continuous usage and harsh environments. They are engineered for reliability and longevity, ensuring consistent performance even in demanding applications.

5. Cost-Effective

Compared to other types of actuators or feedback mechanisms, vibration motors are relatively cost-effective. This makes them an attractive choice for manufacturers looking to incorporate haptic feedback or vibration functionality in their products without significant cost implications.

FAQs about Vibration Motors

Now, let’s address some frequently asked questions about vibration motors:

1. What is haptic feedback, and how does a vibration motor contribute to it?

Haptic feedback refers to the tactile sensation or physical feedback provided to users through vibrations, motions, or forces. Vibration motors play a crucial role in haptic feedback systems by generating controlled vibrations that simulate sensations like taps, clicks, or vibrations.

2. Can vibration motors only use for alerts and notifications?

While devices like smartphones commonly use vibration motors for alerts and notifications, their applications extend far beyond that. Vibration motors find use in gaming controllers, wearables, medical devices, automotive systems, and industrial machinery, among others, to provide haptic feedback, simulate realistic sensations, or convey information.

3. Can vibration motors be customized for specific applications?

Yes, vibration motors can be customized to suit specific application requirements. Manufacturers can adjust parameters like vibration intensity, frequency, and duration to meet the desired needs of a particular device or system.

4. Are vibration motors silent in operation?

Vibration motors produce vibrations that can create audible noise, especially at higher intensities. However, advancements in motor design and engineering techniques have significantly reduced noise levels, making vibration motors quieter and more efficient.

5. Can vibration motors be controlled electronically?

Yes, vibration motors can be controlled electronically by adjusting the voltage, pulse width, or frequency of the electrical signals supplied to them. This allows for precise control over the intensity and pattern of vibrations produced.

6. Are vibration motors easy to integrate into electronic devices?

Yes, vibration motors are designed for easy integration into electronic devices. They often come with standard mounting options and connectors, simplifying the integration process for manufacturers.

Conclusion

Vibration motors are integral components in modern electronic devices, providing tactile feedback, haptic sensations, and alerts. Their compact size, reliability, and versatility make them suitable for a wide range of applications across industries such as mobile devices, gaming, automotive, medical, and more. With their ability to enhance user experiences and convey information through vibrations, vibration motors continue to play a vital role in technological advancements.

So the next time your smartphone buzzes in your pocket or your gaming controller rumbles in your hands, remember the humble vibration motor that brings those sensations to life!

You can follow us on LinkedIn

I am a highly motivated and skilled individual with a passion for Electrical engineering. I have 1 year of experience in Robotics and Electrical engineering, which has allowed me to develop a strong set of skills in PLC, Painting Robots, SCADA. I am a quick learner and am always looking for new challenges and opportunities to expand my knowledge and skills. I am a team player and enjoy working with others to achieve a common goal. Successfully completed many projects for a various clients in the automobile sector.

Thank You