Types of Condenser

Industry uses different types of Condensers. the condenser is a mechanical device that uses to put down hot vapor or steam into the liquid.

Condensers are an essential part of many industrial processes, from refrigeration and air conditioning to chemical processing and power generation. But with so many types of condensers available, choosing the right one can be a daunting task.

Today we will explore the different types of the condenser and their advantages and disadvantages, to help you make an informed decision when selecting a condenser & motor for your application.

Air-Cooled Condensers

Air-cooled condensers are the most common type of condenser in use today, particularly in small to medium-sized applications. As the name suggests, they use air to remove heat from the refrigerant, rather than water or another coolant. This makes them easy to install, as they do not require a water supply or drain, and they are also less expensive than water-cooled condensers.

However, air-cooled condensers have some limitations. They are less efficient than water-cooled condensers, as air is a less effective heat transfer medium than water. This means that they are not suitable for high-temperature applications, as they cannot remove heat as effectively as water-cooled condensers.

They also require a significant amount of space for the air to circulate around the condenser coils, which can be a problem in cramped or enclosed spaces.

Water-Cooled Condensers

Water-cooled condensers use water as a coolant to remove heat from the refrigerant. They are more efficient than air-cooled condensers, as water is a better heat transfer medium than air. This makes them suitable for high-temperature applications, as they can remove heat more effectively than air-cooled condensers.

However, water-cooled condensers have some disadvantages. They require a constant supply of water, which can be a problem in areas with water shortages or where water is expensive. They also require a drain for the water to be discharged, which can be difficult to install in some applications. Finally, they are more expensive than air-cooled condensers, due to the additional cost of the water supply and drain systems.

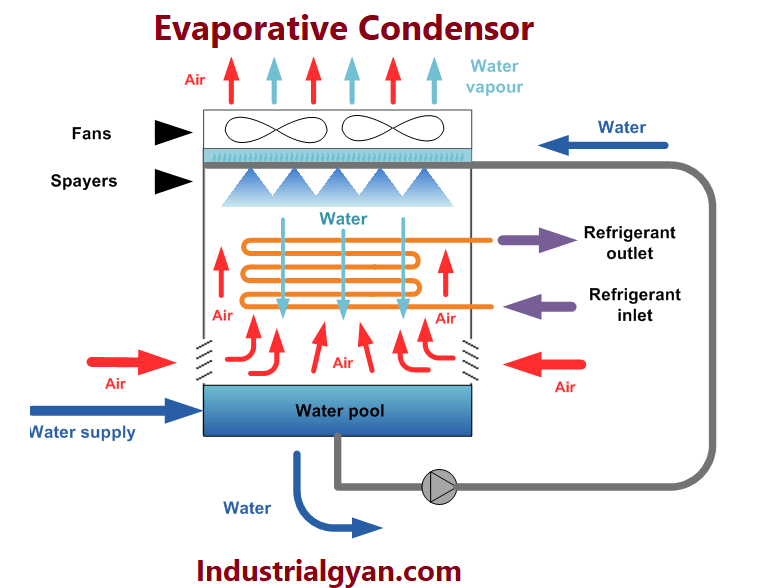

Evaporative Condensers

Evaporative condensers are a type of water-cooled condenser that uses evaporation to remove heat from the refrigerant. They work by spraying water over the condenser coils, which then evaporates, taking heat with it. This makes them very efficient, as the evaporation process provides a significant amount of cooling.

Evaporative condensers have some advantages over other types of condensers. They are very efficient, particularly in high-temperature applications, and they require less water than other types of the water-cooled condensers. They also do not require a separate drain, as the water is evaporated and carried away with the air.

However, evaporative condensers have some limitations. They are more expensive than other types of condenser, due to the additional equipment required to spray water over the coils. They also require regular maintenance, as the water spray nozzles and distribution system can become clogged with debris.

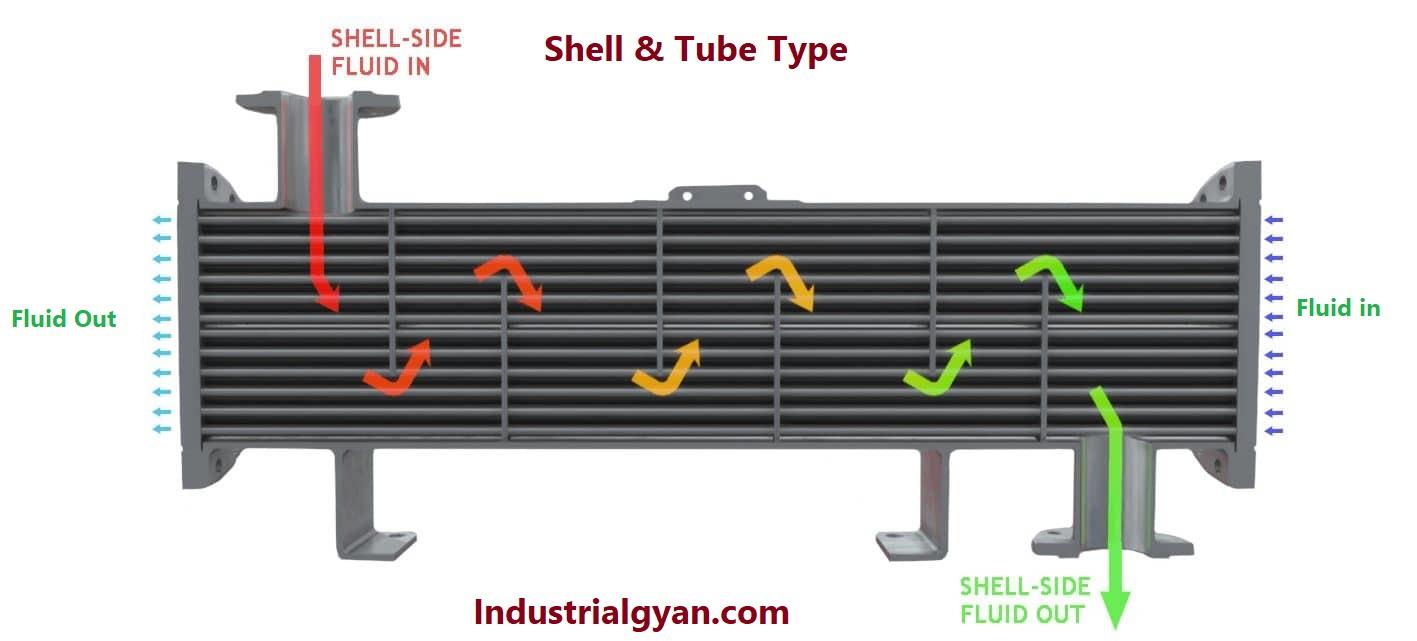

Shell-and-Tube Condensers

Shell-and-tube condensers are a type of water-cooled condenser that uses a shell-and-tube design to remove heat from the refrigerant. The condensers contain a series of tubes surrounded by a larger outer shell. Water pumps through the tubes, and the refrigerant flows through the shell, facilitating the transfer of heat from the refrigerant to the water.

I am an electrical & automation engineer with extensive experience in Design, PLC programming, SCADA development, and IoT integration. I have a strong background in the industry, focusing on the Design & Development of Hardware, Software &Industry 4.0 technologies, and the integration of intelligent manufacturing systems.

I have a deep understanding of electrical principles and am proficient in various programming languages, including Ladder Logic, Structured Text, and Python. In addition, I have experience with various PLC, SCADA & IoT technologies and a track record of successful integration projects for various clients.